A collaborative research team from the Institute of Metal Research (IMR) of the Chinese Academy of Sciences and Nanyang Technological University in Singapore, has revealed the dual and dynamic role that sulfate-reducing bacteria (SRB) play in both accelerating and later partially mitigating the corrosion and cracking of high-strength steel pipelines to transport oil, gas, and hydrogen.

The study was published in Acta Materialia on December 23.

Microbiologically influenced corrosion, particularly from SRB, poses a significant challenge to pipelines buried in soil or submerged in seawater. These microbes can significantly shorten a pipeline's lifespan; however, the detailed interplay between their biological activity, chemical corrosion, and mechanical failure has been poorly understood.

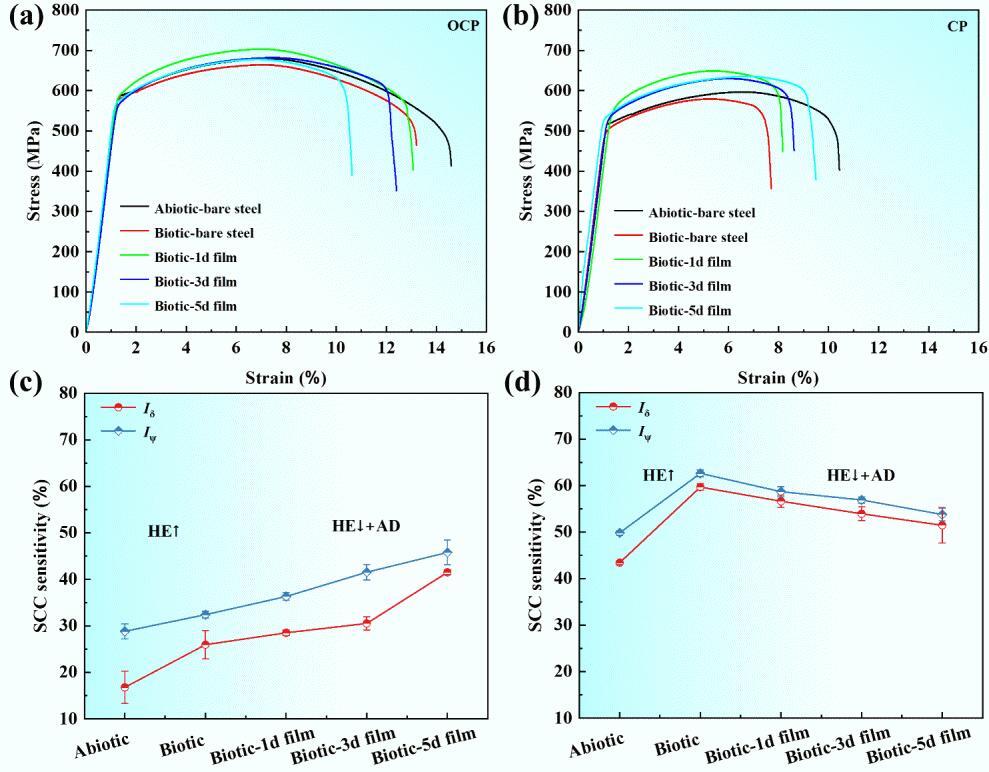

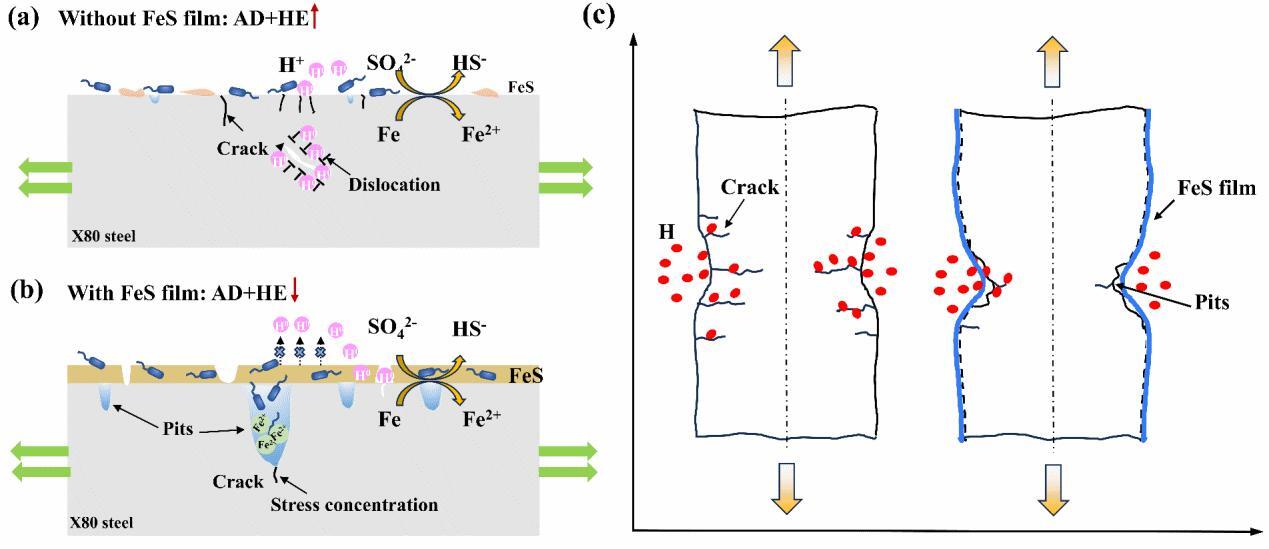

In this study, the researchers investigated X80 high-strength pipeline steel and found that SRB activity has a time-dependent dual effect. In the early stages, SRB significantly accelerate the initiation of stress corrosion cracking by promoting localized metal dissolution and by facilitating the generation and uptake of hydrogen into the steel, which embrittles the material.

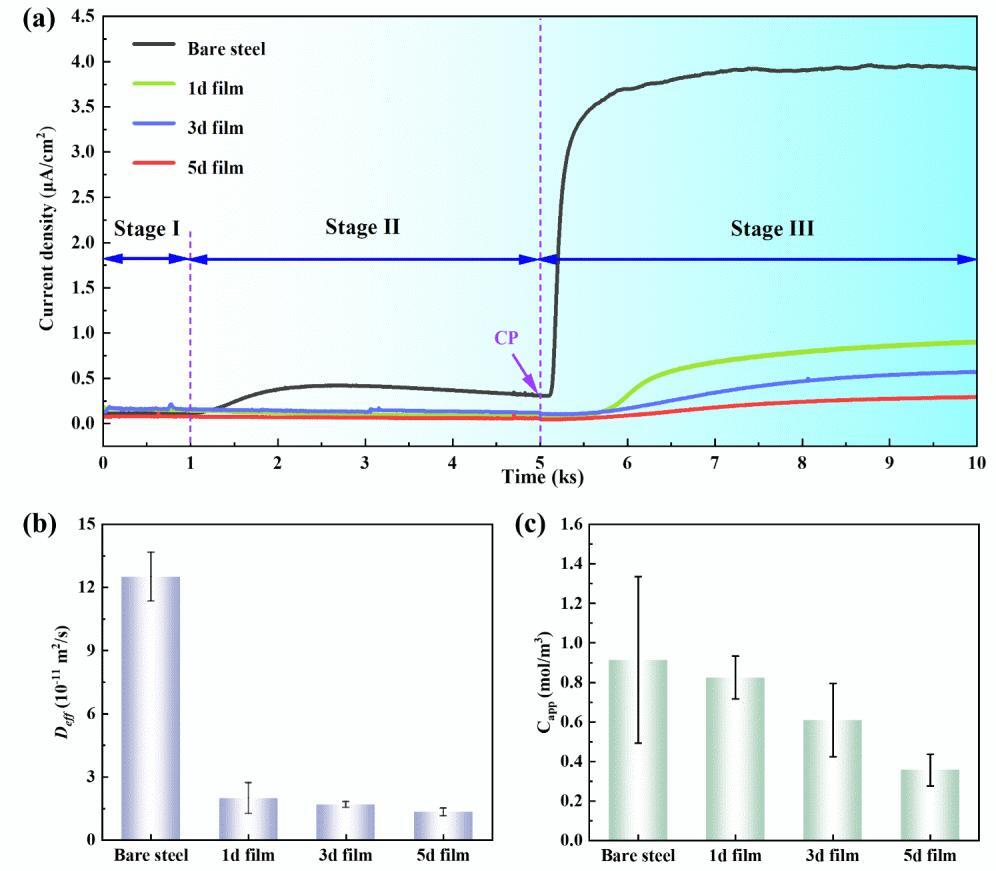

However, as corrosion progresses, SRB metabolism leads to the formation of a unique biogenic film rich in iron sulfide (FeS) on the steel surface. This film exhibits a surprising protective property. Electrochemical tests showed that the FeS film acts as a barrier to hydrogen, substantially reducing the amount of hydrogen that can enter and diffuse through the steel. This inhibitory effect was further confirmed by theoretical calculations.

This critical finding means that, under certain conditions such as when cathodic protection is applied to a pipeline, the FeS film can alter the dominant cracking mechanism. It reduces the contribution of hydrogen embrittlement, slowing and localizing the corrosion process.

By revealing the previously unrecognized "dual role" of SRB, this work offers a more comprehensive scientific basis for assessing the long-term safety of pipelines and for designing smarter corrosion protection strategies in microbial environments.

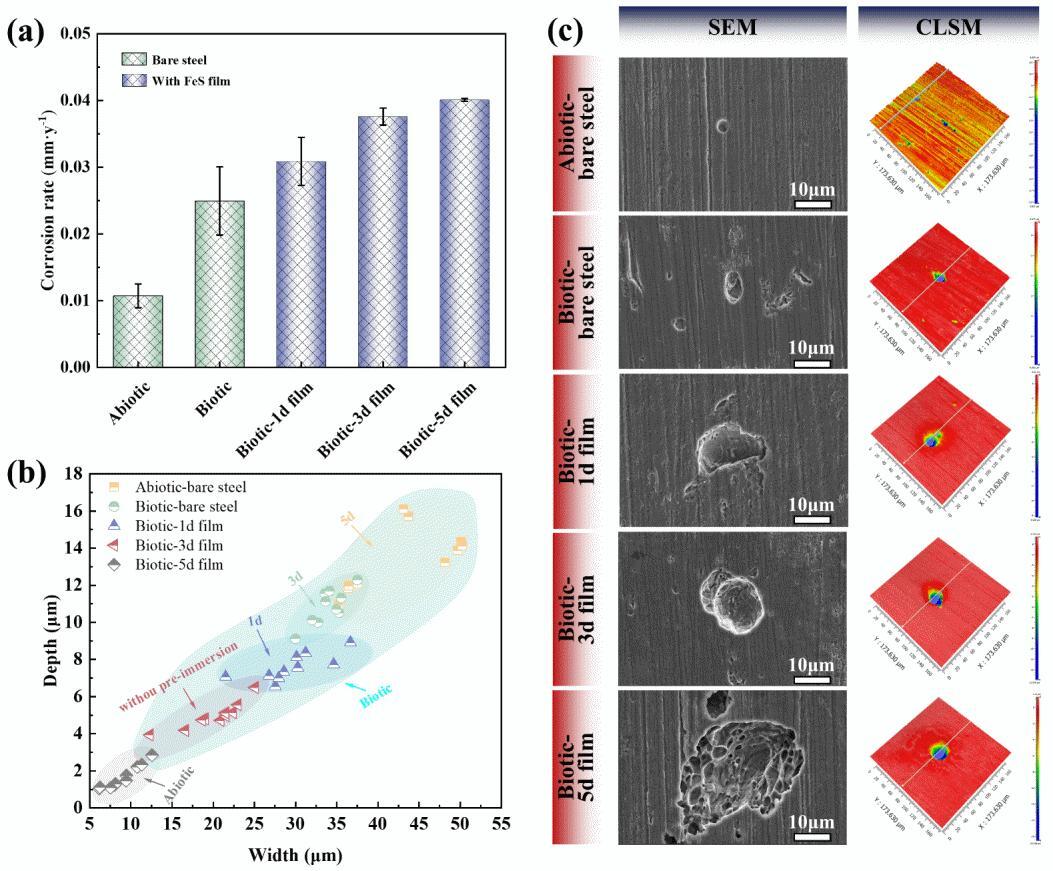

Microbial corrosion behavior of X80 steel: (a) corrosion rate; (b) statistical analysis of pit depth; (c) SEM morphology of the deepest pit and its corresponding 3D surface profile. (Image by IMR)

Hydrogen permeation behavior of X80 steel covered by microbiological corrosion product film: (a) hydrogen permeation current density–time curves under −1.1 V vs. SCE cathodic polarization; (b) effective hydrogen diffusion coefficient (D_eff); (c) apparent hydrogen concentration (C_app). (Image by IMR)

Stress corrosion cracking susceptibility test results for X80 steel covered by microbiological corrosion product film: (a, c) stress–strain curves and SCC susceptibility of X80 steel without cathodic protection; (b, d) stress–strain curves and SCC susceptibility of X80 steel under −1.1 V vs. SCE cathodic protection. (Image by IMR)

Schematic diagram illustrating the mechanism of biogenic FeS film in regulating stress corrosion cracking of X80 steel in an SRB environment.(Image by IMR)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)