Molybdenum (Mo) and its alloys have attracted much attention because of their excellent properties.

A type of nanoscale zirconium carbide (ZrC) dispersion strengthened Mo alloy with high strength and excellent ductility has been developed by researchers from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences (CAS) and the Nuclear Power Institute of China. Related results were published in Acta Materialia.

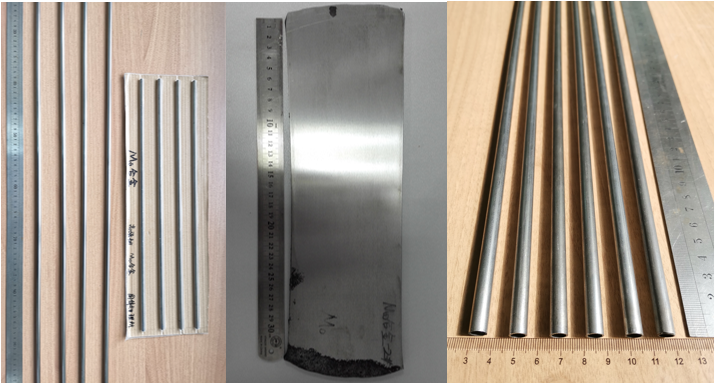

The performance of this nanostructured Mo-ZrC alloy, obtained through powder metallurgy and rotary swaging, was impressive, according to the researchers.

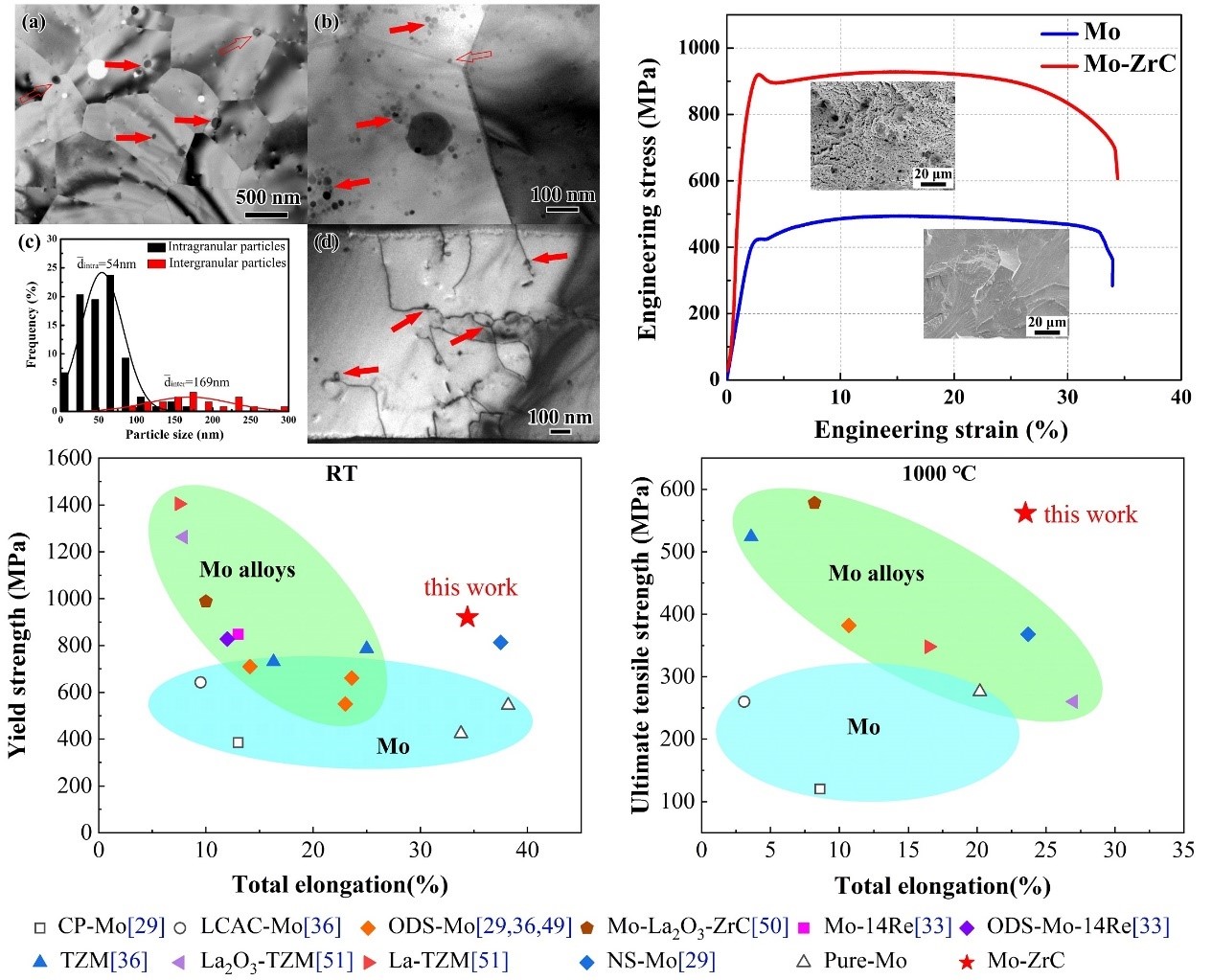

At room temperature, the yield strength of it is 920 MPa, 26% higher than titanium-zirconium-molybdenum (TZM) alloy currently used on the market. The total elongation is 34.4%, more than twice that of TZM.

The researchers also tested it at 1,000 ℃ and 1,200 ℃.

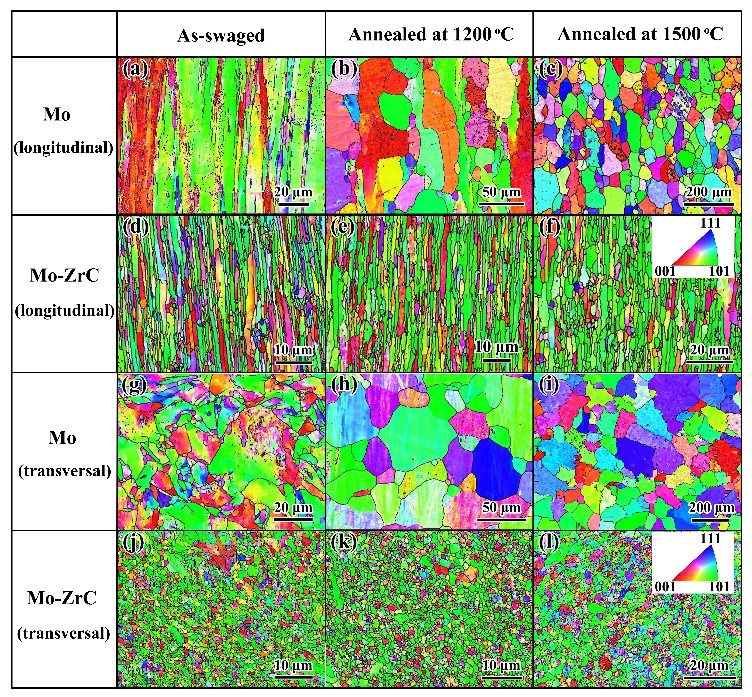

"The recrystallization temperature of the Mo-ZrC alloy is around 1,400 ℃," said LIU Rui, who conducted the study, "which indicates that the material has significant thermal stability."

He further explained the structure of the alloy.

Through computational simulations, the researchers found that segregation of some interstitial impurities, such as oxygen, at grain boundaries (GBs) is the main cause of GB embrittlement and low ductility of the Mo alloy, and interstitial carbon atoms and ZrC particles can effectively improve the strength of the GB.

On this basis, they used nanoscale ZrC particles with high melting point, high hardness and low neutron absorption cross section as the strengthening phase, and refined the grain size by dislocation pinning and GBs to improve the strength and thermal stability.

"The prepared high-performance Mo-ZrC alloy has good application prospects in space reactors and high-temperature industries," said LIU said, "and we hope to apply this strategy to other high-temperature refractory alloys."

The work was supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, the Foundation of Science and Technology on Reactor Fuel and Materials Laboratory and the HFIPS Director's Fund of CAS.

Microstructure and room temperature engineering strain-stress curve of nanostructured Mo-ZrC alloy, and comparison of tensile properties of various Mo-based materials at room temperature and 1,000 ℃. (Image by JING Ke)

Grain structure of Mo-ZrC alloy and pure Mo before and after high temperature annealing. (Image by JING Ke)

Mo-ZrC alloy rods, plates and tubes. (Image by JING Ke)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)