Biomass is one of the most widely distributed renewable energy sources on the earth. Lignocellulose is one of the most abundant biomass resources, mainly including cellulose, hemicellulose and lignin. Among them, cellulose and partial hemicellulose can be decomposed into fermentable sugar by cellulase to produce biofuel and other high value-added products. The hydrolysis of cellulose in natural form not only consumed large number of enzymes, but also resulted in low enzymatic hydrolysis yield (< 20%) because of the compact structure in lignocellulose.

In particular, the lignocellulosic "biomass recalcitrance" result in the low enzymatic hydrolysis yield, the high cost and the great conversion difficulty. Therefore, some structural modifications of lignocellulosic materials have been performed to destroy the complex lignocellulosic structure and enhance the enzymatic hydrolysis yield of biomass material, and the development of lignocellulose pretreatment process has gained extensive attention at home and abroad.

Recently, researchers in the Biophysics Laboratory at the Institute of Modern Physics of the Chinese Academy of Sciences have made new progress in the study of lignocellulosic pretreatment by 12C6+ irradiation to improve the enzymatic hydrolysis yield and its mechanism, using the experimental platform at the Heavy Ion Research Facility in Lanzhou (HIRFL).

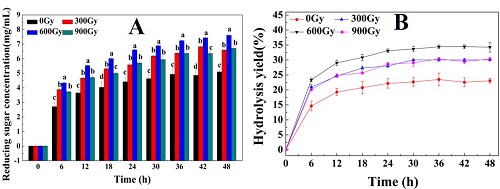

Researchers found that the groups with 12C6+ irradiation pretreatment could significantly improve the enzymatic hydrolysis yield and reducing sugar yield of sweet sorghum straw (SSS) compared with that of the control.

Especially, the highest enzymatic hydrolysis yield of SSS was obtained with 600 Gy of 12C6+ irradiation pretreatment. The hydrolysis yield was 34.43% at 36 h of enzymatic digestibility, which was a 46.7% of improvement in enzymatic hydrolysis yield compared with untreated SSS (23.43% of hydrolysis yield) (Fig.1).

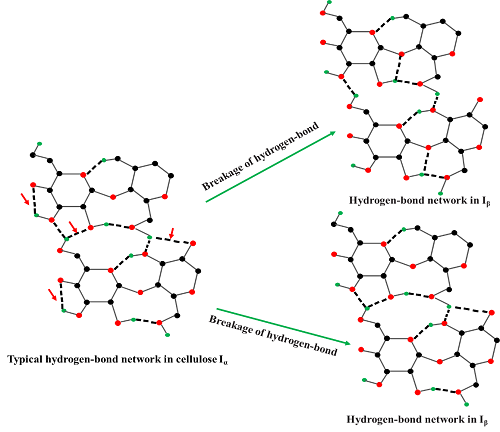

In addition, the mechanism in enhancing enzymatic hydrolysis of SSS pretreated by heavy ion beams irradiation (HIBI) was investigated. XRD pattern concluded that crystalline structure of SSS were disrupted and removed partially the hemicellulose and lignin during various doses of HIBI pretreatment.

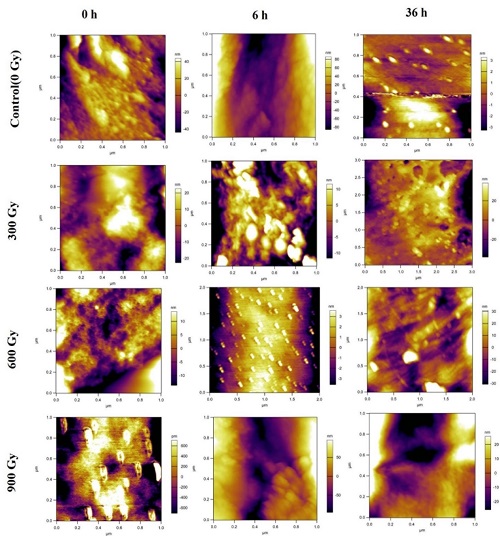

Furthermore, the destruction of surface ultrastructure in SSS polysaccharides was major reason for improving the hydrolysis yield (Fig.3).

This research applies heavy ion beam to modify the lignocellulose for the first time, destroying the "biomass recalcitrance" in lignocellulose. XRD, FTIR and AFM are used to characterize and visualize the SSS pretreated by HIBI, which provides a detailed data support for the explanation of the mechanism of HIBI pretreatment.

Additionally, the results demonstrated that HIBI could be chosen as an effective physical pretreatment process for enhancing enzymatic hydrolysis yield of lignocellulosic biomass, filling a gap in the field of biomass pretreatment.

The research was published in Carbohydrate Polymer with the title of "Enhancing enzymatic hydrolysis yield of sweet sorghum straw polysaccharides by heavy ion beams irradiation pretreatment".

The research was supported by the National Natural Science Foundation of China and key projects of the Chinese Academy of Sciences.

Fig. 1. Enzymatic digestibility of SSS pretreated with different doses of HIBI ((A) Reducing sugar concentration from SSS; (B) Enzymatic hydrolysis yield of SSS) (Image by WANG Shuyang)

Fig. 2. The transformation model in polymorphs (α→β) of cellulose I (Red arrows indicate the broken hydrogen-bonding in SSS during HIBI pretreatment) (Image by WANG Shuyang)

Fig. 3. Surface morphology of SSS during enzymatic hydrolysis process (Image by WANG Shuyang)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)