Nacre is famous for its ingenious hierarchical brick-and-mortar structure. It demonstrates how nature achieves brilliant mechanical properties. So nacre is one of the most studied natural structural materials, and the fabrication of artificial nacre-inspired materials has been motivating for a long time.

High performance nacre-mimetic materials, especially these with large-sized 3D bulk form, are attracting much more attention due to their promising applications for biomedicine, construction and aerospace, etc. Various methods have been exploited during the past two decades to replicate nacre features, resulting in artificial nacre-like materials with impressive structural and mechanical similarity. However, it is still a significant challenge to produce large-sized 3D bulk artificial nacre, especially for further scale-up.

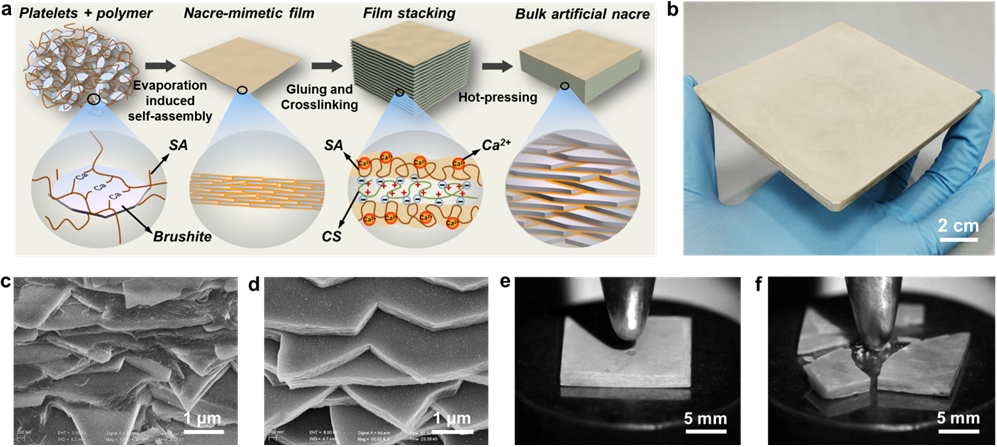

Fabrication and characterization of bulk artificial nacre. (a)Schematic illustration of the bottom-up assembly process of bulk artificial nacre.(b) Large as-fabricated bulk artificial nacre. (c, d) Cross-section of the artificial nacre c and natural Cristaria plicata nacre d show the similar fractured layered microstructure. (e, f) Artificial nacre e and Cristaria plicata nacre f under the same strength of impact, illustrating the higher impact resistance of the artificial nacre. (Image by GAO Huailing)

To address the chanllenge, a research group led by Prof. YU Shuhong from the University of Science and Technology of China (USTC) recently developed an efficient mass-productive bottom-up assembly strategy based on their previous work about biomimetic synthesis of 3D bulk nacre-like material via matrix-directed mineralization, facilely producing large-sized, 3D bulk artificial nacre with comprehensive mimicry of both hierarchical structures and mechanical properties of natural nacre.

Furthermore, by collaborating with Prof. NI Yong's group, they proposed the multilevel toughening mechanisms of this artificial nacre that was found in its natural counterparts.

Owing to the advantages of this developed method, researchers found that the hierarchical architecture of the designed artificial nacre can be optimized from molecular level to macroscopic level. And this optimization can achieve mechanical performance of the artificial nacre with great superiority to that of natural nacre and many engineering materials.

Specially, this bottom-up strategy has no size restriction or fundamental barrier for further scale-up, and can be easily extended to other material systems, opening an avenue for mass production of high-performance bulk nacre-mimetic structural materials in an efficient and cost-effective way for practical applications.

This work highlights a practical guideline for further development of more high-performance, bioinspired structural materials on the basis of similar bottom-up assembly strategies.

The work was published in Nature Communication titled "Mass production of bulk artificial nacre with excellent mechanical properties".

This work was supported by National Natural Science Foundation of China, Foundation for Innovative Research Groups of the National Natural Science Foundation of China, the National Basic Research Program of China, and the National Postdoctoral Program for Innovative Talents.

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)