A Chinese research team led by Prof. FEI Guangtao of Institute of Solid State Physics, Hefei Institutes of Physical Science, Chinese Academy of Sciences, reported the high temperature oxidation behavior of superlattice nanowire structure, and revealed that the elements diffusion quantity plays an important role in the morphology evolution based on Kirkendall effect.

High temperture oxidation is an effective way to prepare metal oxide hollow nanostructure. The formation mechanism is based on the Kirkendall effect.

So far, Through oxidation of metal at a certain temperature, kinds of nanotubes and hollow nanoparticles, such as CuO, NiO, ZnO and so on have been prepared.

However, studies on metal oxidiation behavior mainly focus on the single component and the oxidation of superlattice nanostructure composed by two kind of metals is very few.

Given this, it is vital to explore the oxidation bahavior of superlattice nanowire through which synthesis and structure control of heterogeneous composite hollow nanostructure could be realized.

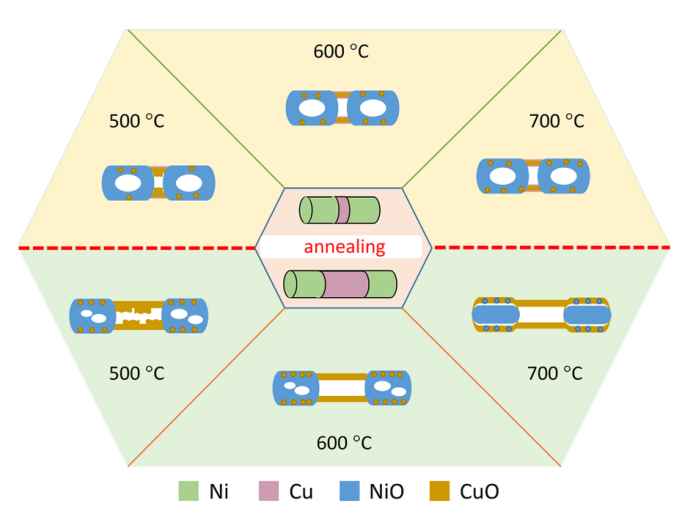

In this work, two kinds of morphologies including CuO nanotube linked core-shell structures and CuO nanotube linked hollow structures were obtained through annealing Ni/Cu superlatice nanowires in air.

The structure can be tuned by adjusting the relative length of Cu segments in Ni/Cu superlattice nanowires and the annealing temperature (Figure 1).

The formation mechanism was analyzed in detail, and the relative diffusion amount of Cu to Ni segments was proved to be the key factor to influence the annealed sample morphology.

When the relative diffusion quantity is little, the oxidation behavior of Ni segments is similar to the oxidation of pure Ni, the oxidation process is mainly external oxidation, accompanying with the hollow structure formed.

while the relative diffusion quantity is large, the oxidation of Ni segments doped with Cu atoms can be regarded as the oxidation process of Ni-Cu alloy at the nanoscale.

The formed Cu2O shell layer can offer sufficient O source to oxidize internal nano-sized Ni, which leads to Ni experiencing simultaneous external and internal oxidation, and makes the final oxidation product an internal oxide of Ni lying beneath of a mixed shell layer of CuO and NiO.

This work not only sheds light on the design and controllable synthesis of the functional heterogeneous composite hollow nanostructures, but also deepens the understanding of the oxidation behavior of heterostructure and expands the Kirkendall effect in nanoscale.

Their work was detailed in Scientific Reports entitled “Necklace-like NiO-CuO Heterogeneous Composite Hollow Nanostructure: Preparation, Formation Mechanism and Structure Control”.

Figure 1. The schematic of morphology evolution of Ni/Cu nanowires after annealing at different temperatures. (Image by XU Shaohui)

Figure 2. The schematic of the morphology transformation of Ni/Cu nanowires with shorter Cu segment (a) and longer Cu segment (b) when annealing in air. (Image by XU Shaohui)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)