Li-ion batteries dominate the secondary battery market due to their features like high energy conversion efficiency, low self-discharge rate, wide working temperature range and no memory effect. Since high capacity, cycling stable, weight-light and small batteries are highly desired by high-tech products such as electric vehicles and unmanned planes, it becomes much more significant to explore high capacity including gravimetric and volumetric capacities than ever before.

Dr. LIU Jinyun, a member of Prof. LIU Jinhuai and Prof. HUANG Xingjiu’s research group in Institute of Intelligent Machines, Hefei Institutes of Physical Science achieved a series of research progresses on nanostructured electrodes in which a three-dimensional nanoelectrode with high volumetric capacity was fabricated on the basis of a previously built up general method. And a new mechanism for the capacity decay of nanostructured Li-ion batteries was proposed and demonstrated by modeling. Their findings have been published in Advanced Materials, ACS Nano and Small with titles Hydrothermal Fabrication of Three-Dimensional Secondary Battery Anodes, Mechanically and Chemically Robust Sandwich-Structured C@Si@C Nanotube and High Full-Electrode Basis Capacity Template-Free Three-Dimensional Nanocomposite Secondary Battery Anodes, respectively.

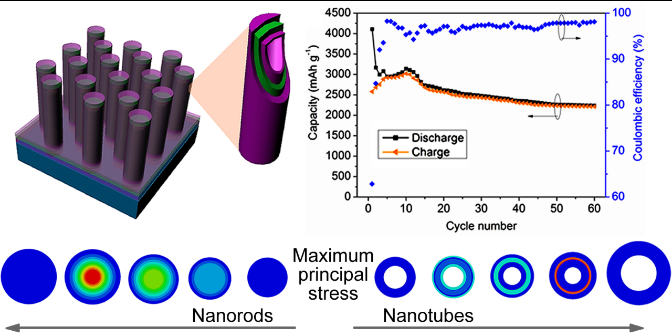

Nanostructured electrodes possess many fascinating features, such as highly-active electrodes, short pathway for ion diffusion and electron transfer. Researchers focused on the instinct capacity decay mechanism firstly, then constructed high-capacity and stable nanoelectrodes, as well as established a general fabrication approach. For example, a Si/C nanotube array electrode was proposed. Within the nanotube, silicon was coated with carbon layers on both sides (Figure 1).

This design is able to reduce the influence of solid electrolyte interphase to battery stability during cycling. Through an in-situ SEM technology, the dynamic volume and structure changes of nanotubes during lithiation/delithiation is demonstrated (Figure 2).

Moreover, a fatigue-induced capacity decay mechanism was put forward and demonstrated on the basis of theoretical modeling.

In addition, on the basis of the general preparation method on three-dimensional nanoelectrode, a template-free nanoelectrode was fabricated (Figure 3). Over 200 cycles, the presented electrode provides a full electrode basis capacity of about 1000 mAh cm-3), far exceeding the current commercial graphite-based anode (550 mAh cm-3).

The high performance of this nanoelectrode makes microscale batteries appliable in wearable electronics.

These progresses were achieved due to the collaboration between the Institute of Intelligent Machines and the University of Illinois at Urbana-Champaign. As the research goes on, further research findings on the high performance nanoelectrodes and their electrochemical properties are expected.

Figure 1. Sketch map of the C@Si@C three-dimensional nanotube array; charge-discharge capacity and Columbic efficiency; modeling contours of the maximum principal stress distribution during lithiation. (Image by LIU Jinyun)

Figure 2. (a) SEM images of the C@Si@C nanotube; In-situ SEM images of the nanotube after (b) lithiation and (c) delithiation. (Image by LIU Jinyun)

Figure 3. (a) Cover article on Small; SEM images of (b) three-dimensional SiO2 scaffold and (c) SiO2 @Fe3O4/C electrode; (d) Top-view, (e) cross-sectional, and TEM images of Fe3O4/C nanoelectrode. (Image by LIU Jinyun)

86-10-68597521 (day)

86-10-68597289 (night)

86-10-68511095 (day)

86-10-68512458 (night)

cas_en@cas.cn

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)