As for developing fusion energy, one of the key issues is the research and development of plasma-facing materials (PFMs). In nuclear fusion facilities, the PFMs are exposed to high temperature, high thermal load and high dose irradiation. In this case, performance of PFMs concern the stable operation of fusion reactor. Given this, tungsten materials are considered as one of the most promising candidates for PFMs due to their high melting temperature, high thermal conductivity, high sputtering resistance and low tritium retention. However, as to practical application tungsten materials have their limitations such as room-temperature embrittlement, high ductile to brittle transition temperature (DBTT>400°C), poor machinability, recrystallization embrittlement and irradiation-induced embrittlement.

Since 2012, a study team led by Prof. FANG Qianfeng and Prof. LIU Changsong from the Institute of Solid State Physics, Chinese Academy of Science (ISSP, CAS) have conducted a series of systemic investigations on the strengthening and toughening of tungsten materials through GB purifying/strengthening, oxide/carbide dispersion-strengthening, micro-alloying and hot plastic working. These studies provide a basis for fabricating high performance tungsten alloys with optimal microstructures.

Recently, the study team joined force with LUO Guangnan from the Institute of Plasma Physics (IPP, CAS) and LIU Xiang from Southwestern Institute of Physics (SWIP) conducted an experiment through which they managed to design and manufacture tungsten alloys plate with extraordinary high strength and ductility as well as excellent thermal shock resistance. The design possesses strengthening of the tungsten grain through intragranular ZrC nano-particles pinning and accumulating dislocations, the special coherent interfaces of grain/phase boundaries (GB/PBs) and the diminishing oxygen (O) impurity at GBs, which strengthens GB/PBs and thereby enhances the ductility, strength and plasticity of W alloy. An unprecedented three-point bending as well as tensile ductility and strength, in terms of flexural strain and total elongation to failure, has been derived from the resulting W-Zr-C alloy.

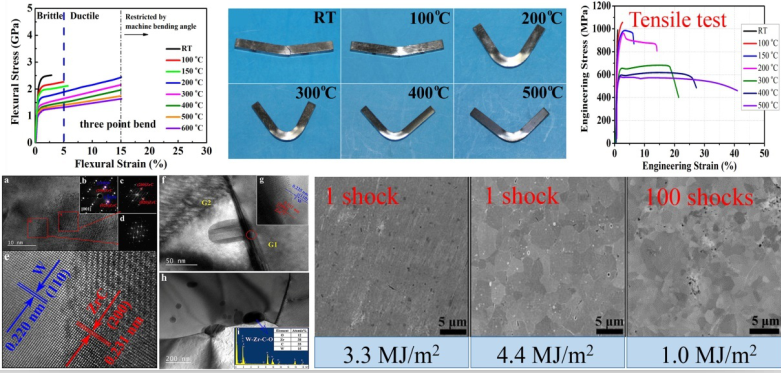

The W-Zr-C alloy thick plates (8.5 mm in thickness) show a high flexural strength of 2.5 GPa and a flexural strain of 3% at room temperature (RT) and a low DBTT of about 100°C. The tensile strength is about 991 MPa at RT and 582 MPa at 500°C, while the total elongation is about 1.1% at RT and as large as 41% at 500°C, respectively. In addition, the W-Zr-C alloy plate can sustain 4.4 MJ/m2 (0.88 GW/m2, 5 ms/pulse) or 100 shots of 1.0 MJ/m2 (1 GW/m2, 1 ms/pulse) transient thermal load without any cracks.

The synergistic effects of strengthening tungsten grain through intragranular ZrC nano-particles dispersion, the completely coherent or semi-coherent interfaces between W matrix and ZrC dispersoids, enhancing GBs by formation of high thermal stability W-Zr-Cx-Oy at GBs as well as fine grains lead to the extraordinary ductility/strength in bulk W-Zr-C alloy. This design idea not only benefits batch production of engineering-applied W alloy but also lays foundation for new alloys with higher ductility and strength.

The study was published in the journal of Scientific Reports entitled Extraordinary high ductility/strength of the interface designed bulk W-ZrC alloy plate at relatively low temperature.

This study was supported by the National Magnetic Confinement Fusion Program (Grant No. 2015GB112000), National Natural Science Foundation of China (Grant Nos.11374299, 51301164, 11375230, 11274305, 11475216), Anhui provincial Natural Science Foundation of China (Grant No. 1408085QE77) and Users with Potential of Hefei Science Center.

Figure 1. Advanced carbide dispersion-strengthened tungsten alloys from laboratory to industrial scale (Image by XIE Zhuoming and LIU Rui)

Figure 2. The mechanical properties, microstructure and heat shock resistance of W-ZrC alloys. (Image by XIE Zhuoming)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)