The owl can fly without making any sound, because different nanostructures of its feather affect sound differently. Gecko can climb on the slippery window, because the microfilaments on its feet generate strong capillary force. Peacock has colorful feather, because the microfilaments on the feather surface reflects natural lights of different wavelength. Current nanostructure manufacturing has disadvantages to produce the bionic structure or equipment at such microscale. The technique developed by the University of Science and Technology of China (USTC) scholars provided possibility to address this problem.

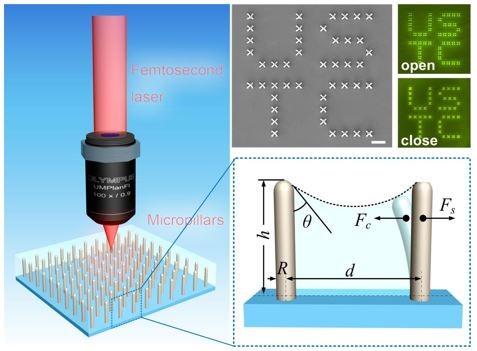

CHU Jiaru and his team from the School of Engineering Science, USTC of Chinese Academy of Sciences, in collaboration with Swinburne University of Technology, combined laser printing and capillary force to build complex, self-assembling microstructures. Producing these microstructures, the researchers used a technique called laser printing capillary-assisted self-assembly (LPCS), which prepared a series of microfilament array with highly controllable and consistent structure, size, mechanical constant and spatial distribution. Through manual control of the surface tension between liquid and the nanostructures, the microfilament array can be freely regulated with high precision, the hierarchical structure self-assembly preparation can be realized, and the micro objects can be selectively captured or released.

The study was published on the Proceedings of the National Academy of Science entitled "Laser printing hierarchical structure with the aid of controlled capillary-driven self-assembly".

"This technique provides vital process for producing bionic structure or equipment at micro-nano scale, also it is a brand new technology for particle screening, capturing and transferring at micro-nano scale," said HU Yanlei from the team. This manufacturing process is easy to control with high yield and environment protecting, which might be applied to analytical chemistry, drug delivery/release, cell biology, microfluidic engineering and other fields in the future.

This study is funded by Natural Science Foundation of China and National Basic Research Program of China (973 program).

Figure: Hierarchical structures prepared by laser printing with the aid of controlled capillary-driven self-assembly. (Image by CHU Jiaru's group)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)