Polymers are essential materials that meet the rapid increasing society needs. Designing next generation of polymeric material is intriguing yet challenging. Glass fibre reinforced plastics (GFRPs) are one of the most widely used composite materials and hold great potential applications due to their high-performance and cost effectiveness. Desired interfacial adhesion are paramount important in order to achieve enhanced affinity between fiber and resin matrix, and to improve the durability of GFRPs.

A research group led by Prof. ZHANG Yagang from Xinjiang Technical Institute of Physics & Chemistry (XTIPC) of the Chinese Academy of Sciences developed a new strategy to control interfacial properties and to improve interfacial adhesion for fibre reinforced polymer composites.

Prof. ZHANG’s group proposed supramolecular quadruply hydrogen-bonding (QHB) interactions offering great potential for smart materials as responsive module to external stimuli such as heat, light, mechanical stress and solvent. The material containing these units could serve as energy dissipater or smart nano-adhesion promoters. The result was published on Current Organic Chemistry.

The researchers then focused on designing better glass fiber reinforced thermal plastics such as polypropylene (PP). Glass fibre reinforced thermoplastics, i.e. PP are one of the most exciting areas in the composites market for both structural and engineering applications. However, glass fibre reinforced thermoplastics often possess poor interfacial adhesion which significantly limits their practical application. The existing traditional coupling agents are facing challenges and limitations of poor interfacial compatibility especially for thermoplastics.

Grafting polymer chains onto the glass fibre (GF) surface holds great promise and could be an effective method to increase the interfacial adhesion of composites based on the mechanism of better interlocking and entanglement with the matrix polymer. The enhanced interfacial adhesion will result in good mechanical properties of the composites.

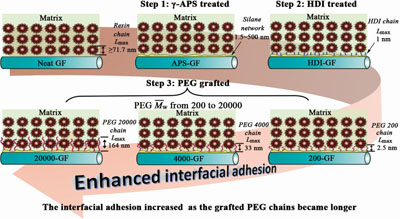

Along this line, researchers developed a three-step surface modification process to control the interfacial properties of the polymer composites. GF was treated by 3-aminopropyl-triethoxysilane (γ–APS), 1, 6-diisocyanatohexane (HDI) and benzylamine, octadecylamine or polyethylene glycol (PEGs) with various chain length stepwise. Researchers grafted organic chain structure onto GF surface. Besides, the surface modified GF was characterized by contact angle measurement, ATR–FTIR and XPS. The results showed that the surface modification method is efficient and successful.

Researchers investigated the effect of the grafting functional groups on the tensile strength of GF/PP composites by tensile test. It is found that the tensile strength of the composites is significantly increased with the lengthening of grafted chain. Thus, modified GF by this method can considerably enhance the tensile strength of PP/GF composites.

This study was published in Engineering Plastics Application, 2015, 43(4), 103-108 and RSC Advances, 2015, 5, 40668–40677.

The work was supported by the One Thousand Talents Program of China, the National Natural Science Foundation of China, etc.

Figure: Three-step surface medication process of glass fibre to control interfacial adhesion for fiber reinforced polymer composites (Image by XTIPC)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)