Ferritic/martensitic steels and austenitic steels are the primary candidate materials for advanced nuclear energy systems. The corrosion resistance of the materials is one of the factors that ensure the safe service of key components. Since the corrosion resistance of materials is highly related to the characteristics of the formed oxide films, it is crucial to investigate the oxide films of candidate materials in high-temperature water.

Researchers at the Institute of Modern Physics (IMP) of the Chinese Academy of Sciences (CAS) selected candidate materials (15-15Ti, 316L and T91) to study their early oxidation behavior in high-temperature steam and the evolution process of oxide microstructure. The results were published in Journal of Materials Science & Technology. The Ni-rich layer in the oxide film of austenitic steels (15-15Ti, 316L) is composed of Fe-Cr spinel oxide and Ni-rich phase. Researchers at IMP found a large number of nanopores in the inner oxide layer which can serve as a rapid gas transport channel for oxidant. They revealed the evolution process of Ni-rich layer and the formation mechanism of nanopores in the inner oxide layer.

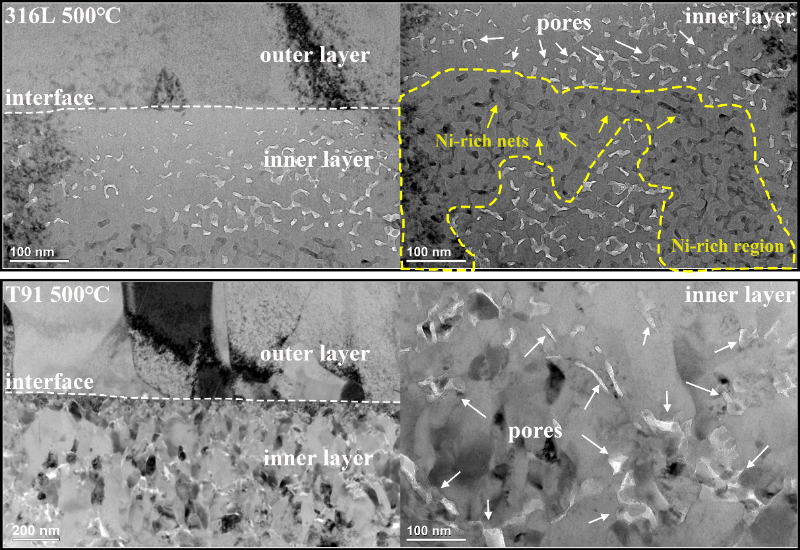

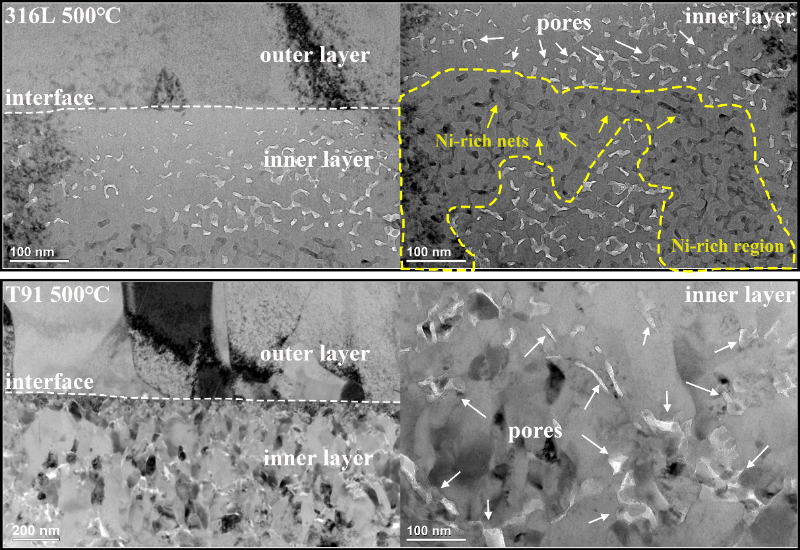

As a product of elements migration and vacancies aggregation during the corrosion process, the pores also have an important influence on the diffusion-dominated oxidation behavior. The researchers used transmission electron microscopy (TEM) to further study the microstructure of the 316L and T91 oxide films, focusing on the microscopic characteristics such as the morphology, distribution, and size of the pores in the oxide film.

High-resolution observations using TEM showed that the inner layer of 316L and T91 oxide films is more porous than the outer layer at the nanoscale, which is different from most previous observations using optical microscopes and scanning electron microscopes. By analyzing the phase, structure and composition of the oxide film, it was clear that the oxidation resistance of 316L is better than T91 in high-temperature steam due to its porous Cr-rich inner oxide layer.

The researchers then revealed the influence mechanism of nanopores on the oxidative corrosion performance of materials. With the model calculation, they suggested that the migration and diffusion of Ni element was the dominant factor in the formation of nanopores in the inner oxide layer of austenitic steel 316L exposed to 350-500 °C steam.

This study provides scientific basis and technical support for the research and development of new anti-corrosion materials.

TEM images of nanopores in 316L and T91 oxide films. (Image by LIU Chao)