Inside a nuclear reactor, long-term exposure to radiation causes structural damage and limits the lifetimes of the reactor components. Nano-crystalline metals (NCs) with the average grain size of about 100 nm have been demonstrated to be radiation tolerant experimentally. This is attributed to the complex across-scale interaction of radiation-created defects, e.g. interstitials and vacancies with grain boundaries (GBs) in NCs.

To understand the defect-GB interaction processes and reveal the across-scale self-healing mechanism in NCs, collaborating with researchers from Institute of Plasma Physics, Hefei Institutes of Physical Science, a nuclear material study team led by LIU Changsong and FANG Qianfeng in Institute of Solid State Physics, Hefei Institutes of Physical Science of the Chinese Academy of Sciences, developed a set of software to investigate radiation effects in NCs.

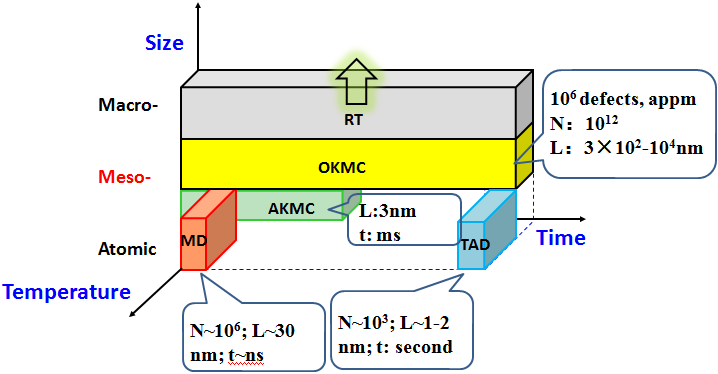

Fig. 1. The length and time scales of different simulation methods in the software. (Image by LI Xiangyan)

The software they developed is composed of temperature-accelerated dynamics (TAD) for simulating defect structure evolution at long time scale, molecular statics (MS) for calculating the energetic properties of defects at 0 K, nudged-elastic band method (NEB) and dimer method (Dimer) for exploring defect potential energy surface, atomic Kinetic Monte Carlo (AKMC) for simulating the defect behavior at atomic scale and micro-second timescale, and object Kinetic Monte Carlo (OKMC) for accessing the defect behavior at micro- and nano-meter length scale and macroscopic time scale (Fig. 1). Other models include the programs to identify a defect in NCs, and visualize defects.

Using the software, the team simulated the behavior of the radiation-created interstitials and interstitial-clusters in NC tungsten (W).

W was chosen as a model system mainly considering that W and its alloys are primary candidate plasma facing materials for the divertor and the first wall in future fusion power reactors, which are subjected to neutron irradiation of 14 MeV and heat flux as high as 10 MW/m2.

Radiation damage not only seriously degrades the mechanical properties of tungsten but also enhances hydrogen retention in the material. To improve resistance of W to irradiation damage, a large fraction of GBs have been introduced to W. Unfortunately, the dynamic picture for annihilating vacancies near the GB in NC W at long timescale in nano-crystal tungsten is still lacked.

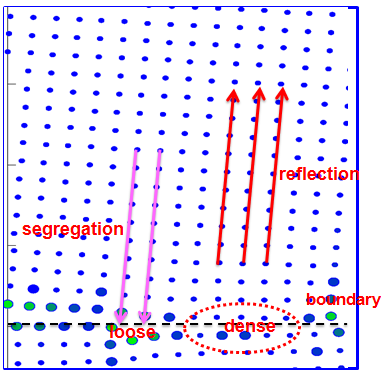

Fig. 2. Illustration of the interstitial reflection by a locally dense GB region and interstitial segregation to a locally loose GB region . (Image by LI Xiangyan)

The team found that the interstitial-cluster was reflected back into the grain interior when approaching the locally dense GB region (Fig. 2). The reflection of an interstitial-cluster by the GB enhances annihilation of bulk vacancies.

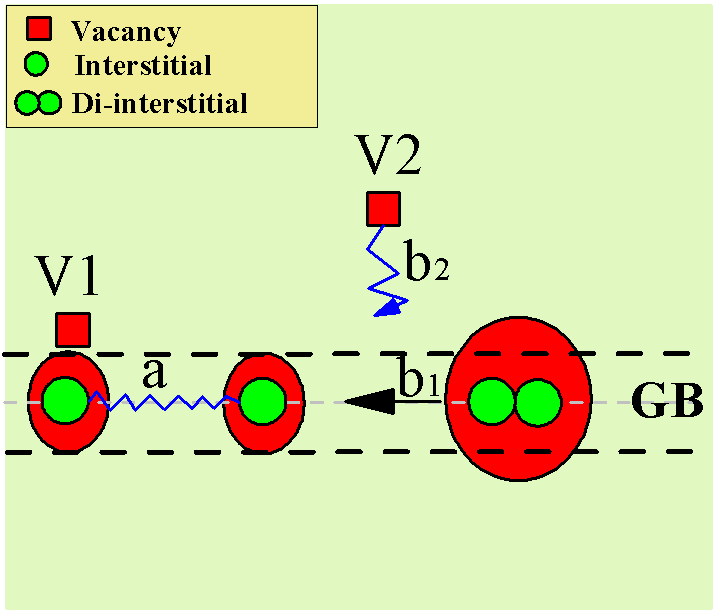

In addition, the dynamic interstitial emission efficiently anneals bulk vacancies (Fig. 3). The single interstitial trapped at the GB firstly moved along the GB quickly and clustered to be di-interstitial therein, reducing its mobility to a value comparable to that for the vacancy diffusion in the bulk.

Then, the bulk vacancy was recombined via coupled motion of the di-interstitial along the GB, the hop of the vacancy towards the GB and the accompanying interstitial emission.

These results suggest that GBs play an efficient role in improving radiation-tolerance of nano-crystal W. They provide good reference for developing nano-structured W as a radiation-tolerant material.

This work was supported by the National Magnetic Confinement Fusion Program, the National Natural Science Foundation of China, and by the Center for Computation Science, Hefei Institutes of Physical Sciences. This research project was part of the CRP (Co-ordinated Research Projects) program carried out under the sponsorship of the International Atomic Energy Agency (IAEA).

The present work was published in Nuclear Fusion entitled "Annihilating vacancies via dynamic reflection and emission of interstitials in nano-crystaltungsten".

Fig. 3. Schematic illustration of the self-healing process in nano-crystalline tungsten. (Image by LI Xiangyan)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)