With the development of electric vehicles technology, an enhanced safe characteristic for the power batteries was urgently needed. Separators and polymer electrolytes have become one of the major bottlenecks to the development of power lithium batteries. Thus it is a compelling challenge to exploit advanced separators and polymer electrolyte to improve comprehensive performance for power lithium batteries.

Prof. CUI Guanglei’s team at Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences, has developed a highly safe cellulose-based lithium battery separator via papermaking process combined with functional modification technology. As compared to commercial polyolefin-based separator, such flame-retardant cellulose-based composite separator possessed excellent flame retardancy, superior heat tolerance and proper mechanical strength. Hence, this high performance cellulose-based separator significantly enhanced the safety performance and service life of the battery. Moreover, the authoritative evaluation showed that cellulose separators have excellent overall performance. The related results have described in Scientific Reports (2014, 4: 3935) and Journal of the Electrochemical Society (2014, 161: A1032-A1038).

There exists large potential hazard when lithium batteries using carbonate organic solvent and polyolefin separator. Above-mentioned hazards will undermine the confidence of consumers and obstruct the commercialization of electric vehicles or hybrid electric vehicles. Thus, the safety issue of state-of-the-arts lithium batteries merits further study. Due to their attractive features of high safety, high flexibility and simple technological process, solid polymer electrolytes have been widely used as advanced and safe polymer electrolyte for application in solvent-free lithium batteries. Inspired by Taichi, professor CUI’s team fabricated a new class of rigid-flexible coupling (CCPL) solid polymer electrolyte. It would be reasonable to achieve a balance among mechanical strength, dimensional thermostability, electrochemical window and ionic conductivity for high-performance LIBs application (Fig.1). This finding has been published in Scientific Reports (2014, 4: 6272).

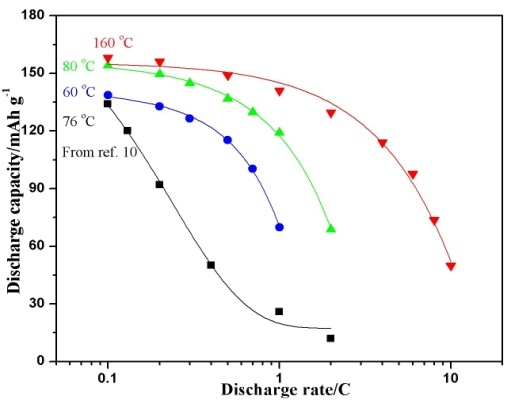

Fig. 1 Design concept of rigid-flexible coupling CCPL solid polymer electrolyte (Image by prof. CUI's group) Fig. 2 Rate performance of LiFePO4/Li cell compared at 60oC, 80oC and 160oC. (Image by prof. CUI's group)

Rate performance is also crucial to practical lithium batteries. Thus, rate capability of lithium iron phosphate (LiFePO4)/lithium (Li) cell using such CCPL solid polymer electrolyte was evaluated at 60 oC, 80 oC and 160 oC (Fig. 2). As compared with pristine poly (ethylene oxide) solid polymer electrolyte, such CCPL solid polymer electrolyte exhibited superior mechanical strength (> 45 MPa), high electrochemical stability (> 4.6 V), excellent rate capability (10 C) and broad temperature range (25 oC-160 oC). Hence, such solid polymer electrolyte is possessed of vast vista in application. At present, QIBEBT researchers are optimizing the related processing technology and ready to carry out demonstration in economical electric cars.

Based upon above-mentioned series of work, the team was invited to present a review paper in Progress in Polymer Science. This paper introduces the application of biomass materials in the aspects of battery material (separators, binders and polymer electrolytes), discusses application prospect of biomass materials in future.

Contact:

Professor CUI Guanglei

E-mail: cuigl (AT) qibebt.ac.cn

Webpage: http://english.qibebt.cas.cn/rh/rs/bagcc/biesy/

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)