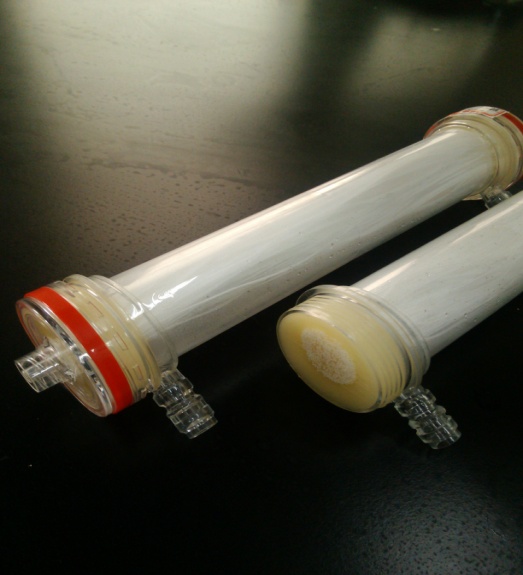

A special type of dialysis membrane module, called dialyzer (Fig.1), is used in the pressure-driven hemodialysis process to remove excess waste products and water from the body. Treatments take from four to six hours and usually are performed three times a week. The materials requirement for blood purification is very strict, and therefore, membrane materials which can be used in clinical application are actually very few. Cellulose and polysulfone are two main membrane materials, and the related technologies are now monopolized by a few companies like Fresenius, Gambro, and Baxter.

|

| Fig.1 PLA module for hemodialysis |

Polylactide (PLA) possesses better bio-compatibility, lower producing cost, and more importantly, it comes from renewable resources and is independent on petroleum based materials. Moreover, PLA is a polymer that can be buried and degraded after use, which is helpful to reduce the reverse impact on the environment.

|

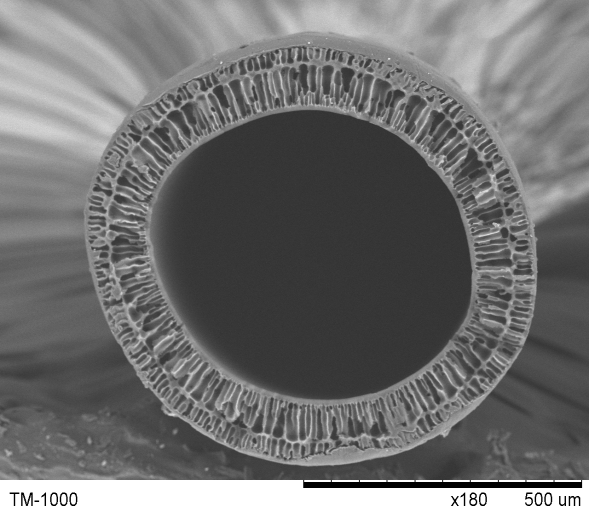

| Fig.2 Cross section of PLA hollow fiber |

Up to now, a related patent has been filed (201210547368.0).

Professor XUE Lixin: xuelx@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/fpm

All Images by ![]()

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)