Oyster Shell Helps Heal Bone Defects

Aug 06, 2014 Email"> PrintText Size

Injuries or surgeries, such as tumor removal, can create gaps in bone that are too large to heal naturally. To help regrow that bone, researchers report a new formulation for bone cement that combines calcium sulfate with oyster shell powder (ACS Appl. Mater. Interfaces 2014, DOI:10.1021/am501448t).

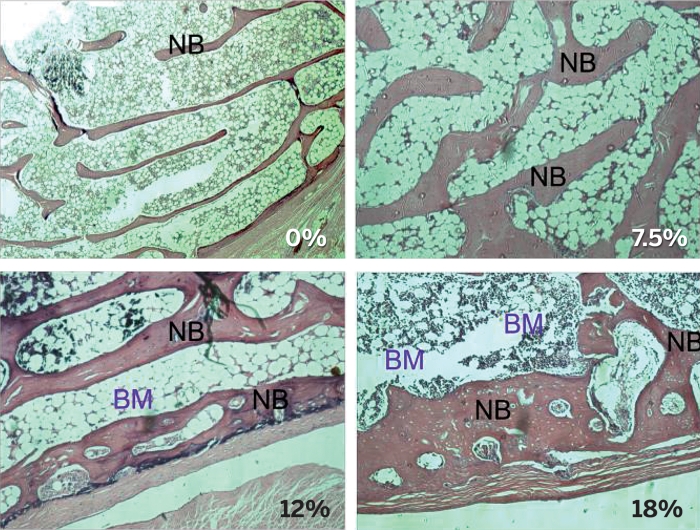

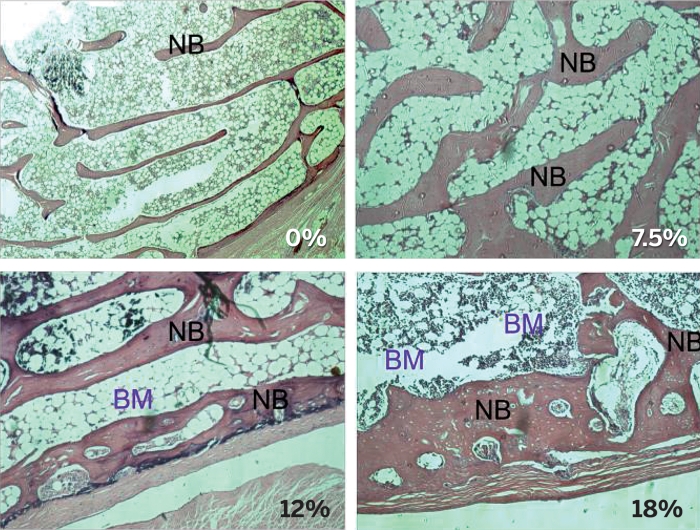

When implanted in the injured femurs of rabbits, composites of calcium sulfate and oyster shell powder caused new bone to grow. The percentages indicate how much oyster shell was in each composite. The material with 18% oyster shell by weight stimulated the most new bone (NB) growth. The BM label designates bone marrow. The micrographs were taken at a 100x magnification. (Image by ACS Appl. Mater. Interfaces)

Currently, the gold standard for fixing bone defects is autografting, in which surgeons harvest bone from elsewhere in the body, such as the hip bone, and use it to fill the gap. However, this procedure is painful and may cause infections or other complications at the site where the bone was taken. Alternatively, surgeons can fill bone defects with putties or cements, such as calcium sulfate. But these materials are not ideal for fostering new bone growth. For example, calcium sulfate degrades more quickly than new bone can form.

"I have seen many clinical dilemmas involving bone defects” and slow or incomplete healing, says Yue Shen, a doctor of orthopedics at Zhejiang University School of Medicine, in China. “I hoped to find an ideal bone substitute to relieve patients’ pain.”

To this end, Shen and colleagues, including Shigui Yanat Zhejiang University, Qing Huang at the Chinese Academy of Sciences, and Lei Peng of Hainan Medical University, combined calcium sulfate with a natural biomineral, oyster shell. Previous research had shown that oyster shell mineralizes in a way similar to new bone in people (Science 2004, DOI: 10.1126/science.1090506). In addition, oyster shell contains signaling molecules that enhance bone growth.

The researchers made composites of calcium sulfate with varying amounts of oyster shell powder. They noticed that the time for the composite to harden increased with the weight percentage of oyster shell powder. The team next tested the new cements by immersing the materials in simulated body fluid, a solution with ion concentrations similar to those in human blood plasma. As expected, pure calcium sulfate degraded rapidly in the fluid. Adding oyster shell to the calcium sulfate decreased the degradation rate. The composite containing 18% oyster shell powder by weight showed the slowest degradation rate over 28 days of soaking. The team also looked for the formation of layers of apatite, a mineral that is a major component of bone, on the composites. Apatite readily deposited on the materials with oyster shell but did not form on pure calcium sulfate.

In another test, the team implanted their composites in 8-mm-diameter holes in the femurs of 24 live rabbits. After eight weeks, they looked for new bone growth. The composite containing 18% oyster powder by weight performed the best. It stimulated the growth of almost twice as much new bone as the pure calcium sulfate.

Melissa A. Grunlan, a biomedical engineer at Texas A&M University, says that the composites have clinically useful properties, such as the ability to tailor the setting and degradation times of the cement by varying the amount of oyster shell.

James H. Henderson, a biomedical engineer at Syracuse University, says, “Although these initial findings look promising, as with any new material for potential medical application, there are many possible challenges ahead.” For example, the oyster shell might elicit an immune response when implanted in a patient, he says. “That’s a critical issue that needs to be examined long before this concept is ready for clinical translation.” (C&EN)

Injuries or surgeries, such as tumor removal, can create gaps in bone that are too large to heal naturally. To help regrow that bone, researchers report a new formulation for bone cement that combines calcium sulfate with oyster shell powder (ACS Appl. Mater. Interfaces 2014, DOI:10.1021/am501448t).

|

| When implanted in the injured femurs of rabbits, composites of calcium sulfate and oyster shell powder caused new bone to grow. The percentages indicate how much oyster shell was in each composite. The material with 18% oyster shell by weight stimulated the most new bone (NB) growth. The BM label designates bone marrow. The micrographs were taken at a 100x magnification. (Image by ACS Appl. Mater. Interfaces) |

Currently, the gold standard for fixing bone defects is autografting, in which surgeons harvest bone from elsewhere in the body, such as the hip bone, and use it to fill the gap. However, this procedure is painful and may cause infections or other complications at the site where the bone was taken. Alternatively, surgeons can fill bone defects with putties or cements, such as calcium sulfate. But these materials are not ideal for fostering new bone growth. For example, calcium sulfate degrades more quickly than new bone can form.

"I have seen many clinical dilemmas involving bone defects” and slow or incomplete healing, says Yue Shen, a doctor of orthopedics at Zhejiang University School of Medicine, in China. “I hoped to find an ideal bone substitute to relieve patients’ pain.”

To this end, Shen and colleagues, including Shigui Yanat Zhejiang University, Qing Huang at the Chinese Academy of Sciences, and Lei Peng of Hainan Medical University, combined calcium sulfate with a natural biomineral, oyster shell. Previous research had shown that oyster shell mineralizes in a way similar to new bone in people (Science 2004, DOI: 10.1126/science.1090506). In addition, oyster shell contains signaling molecules that enhance bone growth.

The researchers made composites of calcium sulfate with varying amounts of oyster shell powder. They noticed that the time for the composite to harden increased with the weight percentage of oyster shell powder. The team next tested the new cements by immersing the materials in simulated body fluid, a solution with ion concentrations similar to those in human blood plasma. As expected, pure calcium sulfate degraded rapidly in the fluid. Adding oyster shell to the calcium sulfate decreased the degradation rate. The composite containing 18% oyster shell powder by weight showed the slowest degradation rate over 28 days of soaking. The team also looked for the formation of layers of apatite, a mineral that is a major component of bone, on the composites. Apatite readily deposited on the materials with oyster shell but did not form on pure calcium sulfate.

In another test, the team implanted their composites in 8-mm-diameter holes in the femurs of 24 live rabbits. After eight weeks, they looked for new bone growth. The composite containing 18% oyster powder by weight performed the best. It stimulated the growth of almost twice as much new bone as the pure calcium sulfate.

Melissa A. Grunlan, a biomedical engineer at Texas A&M University, says that the composites have clinically useful properties, such as the ability to tailor the setting and degradation times of the cement by varying the amount of oyster shell.

James H. Henderson, a biomedical engineer at Syracuse University, says, “Although these initial findings look promising, as with any new material for potential medical application, there are many possible challenges ahead.” For example, the oyster shell might elicit an immune response when implanted in a patient, he says. “That’s a critical issue that needs to be examined long before this concept is ready for clinical translation.” (C&EN)

CAS Institutes

There are 124 Institutions directly under the CAS by the end of 2012, with 104 research institutes, five universities & supporting organizations, 12 management organizations that consist of the headquarters and branches, and three other units. Moreover, there are 25 legal entities affiliated and 22 CAS invested holding enterprisesThere are 124 I...>> more

Contact Us

Chinese Academy of Sciences

Add: 52 Sanlihe Rd., Xicheng District, Beijing, China

Postcode: 100864

Tel: 86-10-68597592 (day) 86-10-68597289 (night)

Fax: 86-10-68511095 (day) 86-10-68512458 (night)

E-mail: cas_en@cas.cn