Newsroom

The gas-liquid-solid slurry reactor, where particles act as catalyst, has been widely applied in energy chemical industry, fine chemistry industry, material chemical industry, and pharmaceutical industry. It has advantages of uniform temperature distribution, perfect mass transfer characteristic, large production capacity with low energy consumption, and convenient operation, making it the first choice for Fischer-Tropsch synthesis.

Solid-liquid separation in the slurry reactor is the critical technique for continuous mass production. In traditional slurry reactors, separate separation and recycling systems are essential, leading to low continuity, high operating costs, unstable output, and poor security.

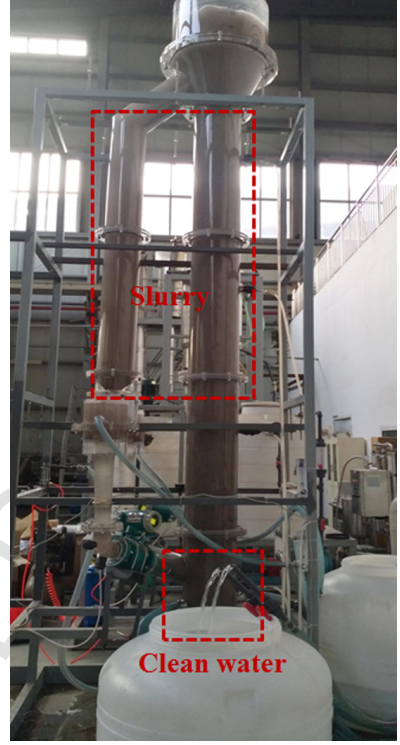

A research group led by Prof. YANG Chao from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences (CAS) developed a novel external loop airlift slurry reactor. In this type of slurry reactor, an external loop airlift reactor and two parallel hydrocyclones for separating the clear liquid from the slurry were integrated to realize the processes of mixing, reaction, and separation simultaneously.

The energy for solid-liquid separation in the hydrocyclones was provided by the circulation power resulted from directional flow in the airlift loop reactors, with no additional energy input desired. Compared with the counterpart of the inner loop, this type of external loop airlift slurry reactor had a large operating space and could be equipped with multiple parallel hydrocyclones. Therefore, the performances of mixing and heat transfer in this new reactor are better; the handling capacity is larger; the operation is more flexible.

Continuous mass production, intrinsic safety, energy conservation and environmental protection can be simply achieved in this reactor, which is promising to be employed for a large scale in many industries.

The researchers systematically investigated the hydrodynamics, mass transfer performance, and solid particle distribution in a 400 L pilot slurry reactor. They found that the clear liquid collected from the overflow of two hydrocyclones was promoted from 0.9 m3/h to 3 m3/h, and the minimum diameter of the solid particles retained in the slurry reactor for circulation decreased substantially from 59 μm to 6.82 μm compared with the internal loop counterpart.

The snapshot of experiments for the gas-liquid-solid system. (Image by GENG Shujun)

"The new type of external loop airlift slurry reactor can be operated continuously with large throughput; this technology is intrinsically safe and can cut down the operation cost considerably. It is a promising slurry reactor, especially for the processes of Fischer-Tropsch synthesis, heavy oil hydrogenation, and p-xylene oxidation," said HUANG Qingshan, the corresponding author of this study.

The related findings were published in Chemical Engineering Science. The research was supported by the National Natural Science Foundation of China, "Transformational Technologies for Clean Energy and Demonstration", the Strategic Priority Research Program of CAS, and Project of CNPC-DICP Joint Research Center.