QIBEBT Developes Efficient Approaches for Lignocelluloses Pretreatment and Utilization

Jul 03, 2014 Email"> PrintText Size

Lignocelluloses are abundant resources on earth. They can be converted to energy, materials, or chemicals to replace the depleting fossil sources. However, it is difficult to achieve efficient conversion due to their natural recalcitrance. The Green Chemical Engineering Center of Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) carried out a series of researches on pretreatment and efficient utilization of inexpensive and renewable lignocelluloses (e.g. corn stover, corn cob, pulp, etc.). The related research progress was published on Bioresour. Technol., J. Agric. Food Chem., Bioproc. Biosyst. Eng., and Carbohyd. Polym., etc.

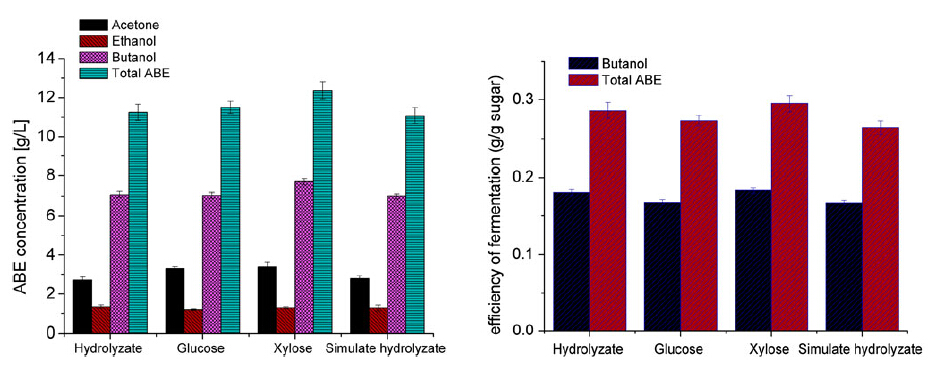

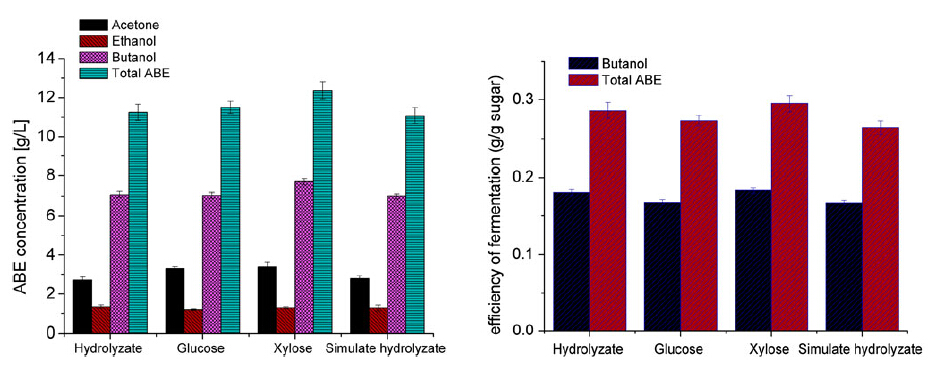

On the basis of previous researches on the alkaline pretreatment of lignocelluloses (Bioresour. Technol., 2012, 125: 193; Biotechnol. Biofuels, 2013, 6:97), the Pretreatment Group led by professor WANG Haisong has further evaluated the Acetone-Butanol-Ethanol (ABE) fermentability of the resulting fermentable sugars after alkali twin-screw extrusion pretreatment and enzymatic hydrolysis. It was found that the ABE fermentability was comparable to the simulated hydrolyzate medium (the solution containing glucose and xylose with the same ratio and concentration). There were no inhibitors for fermentation and the ABE yield could reach 0.112 g/g raw corn stover (Bioproc. Biosyst. Eng., 2014, 37: 913).

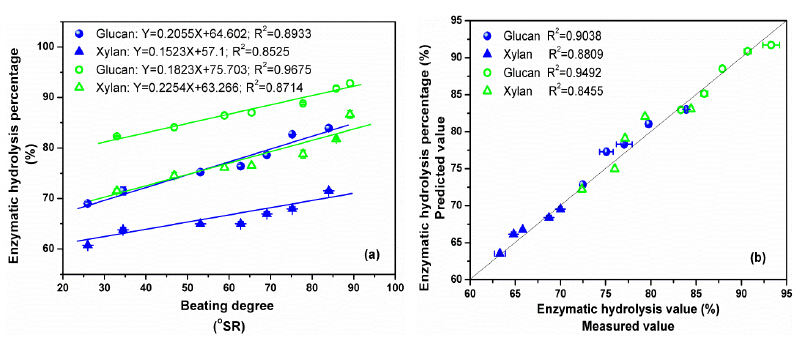

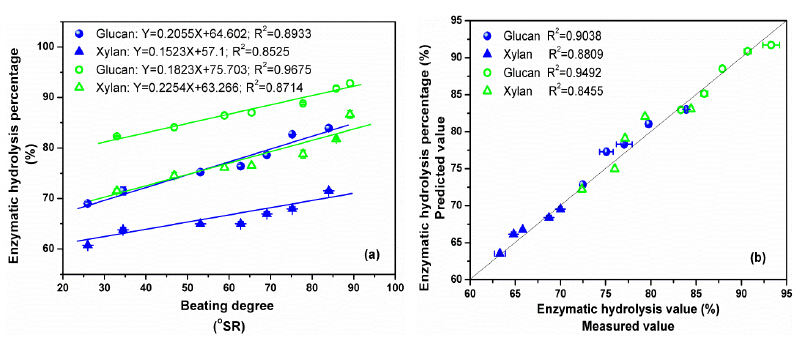

Also, quantitative characterization of the impact of pulp refining on enzymatic saccharification of the alkaline pretreated corn stover was studied. The results showed that the beating degree of PFI refined corn stover was linear with the enzymatic hydrolysis percentage and final total sugar yields. Therefore, the researchers established a simple way to predict enzymatic hydrolysis percentage and final total sugar yields by easily testing the beating degree of refined substrate (Bioresour. Technol., 2014, doi: 10.1016/j.biortech.2014.06.068).

In the meantime, researchers investigated the quantitative analyses of the detailed relationship among the key process parameters in the alkaline pretreatment system. It was found out that the multivariate analysis methods would be a useful tool for optimizing and monitoring the process of biomass conversion in the future commercial production (BioResources, 2014, 9(2): 2757).

Fig. 1 Comparison of the ABE fermentability of the alkali twin-screw extrusion pretreated corn stover and the simulate hydrolyzate

Fig. 2 The relationship between beating degree and enzymatic hydrolysis percentage, and the prediction of enzymatic hydrolysis percentage by testing beating degree of the refined corn stover

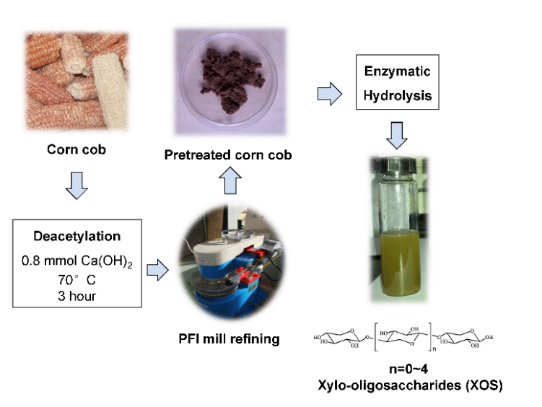

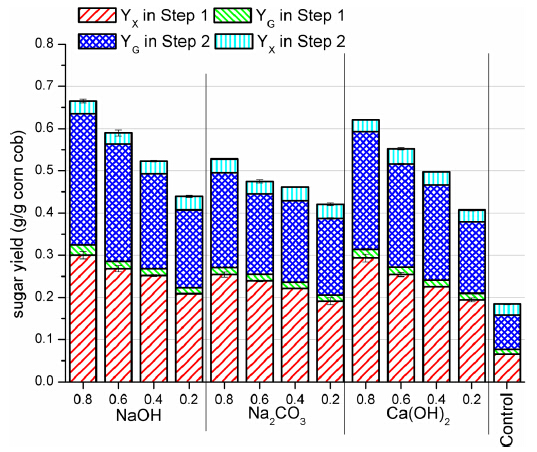

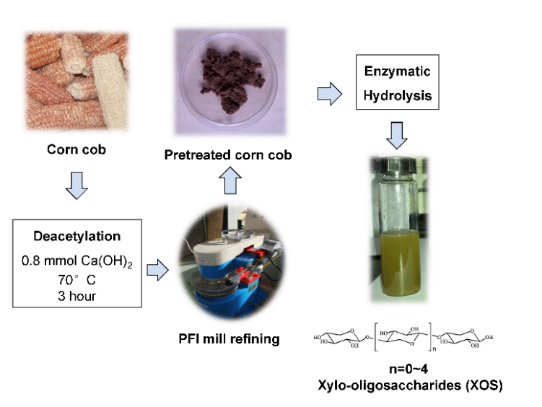

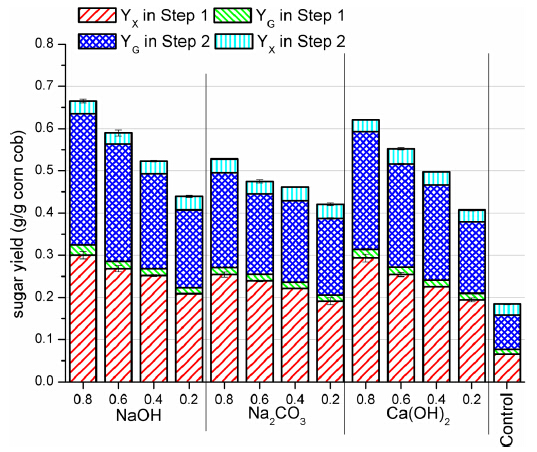

The researchers also developed a novel approach by combining deacetylation and PFI refining for the improvement of a two-stage enzymatic hydrolysis of corn cob. This approach could efficiently obtain xylo-oligosaccharides (XOS) and glucose separately. In stage one, the resulting enzymatic hydrolyzate contained 56.4% XOS, which was higher than the standard concentration of functional XOS, thus it could be used in the field of medical care, dairy beverage, and food. In stage two, the enzymatic hydrolyzate contained 83.8% of glucose, and the total sugar yields of the two-stage enzymatic hydrolysis were 86.4%. Hence, this approach provided the reference for the pretreatment and full utilization of corn cob (J. Agric. Food Chem., 2014, 62, 4661).

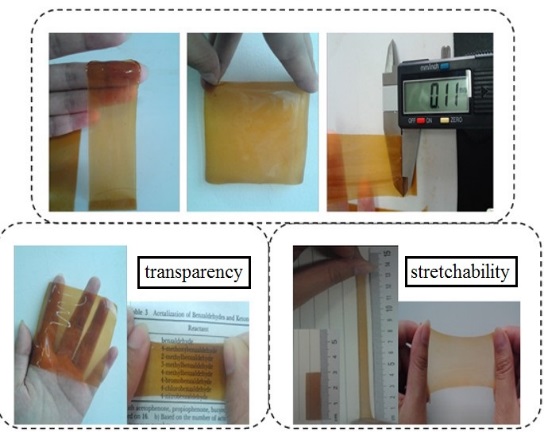

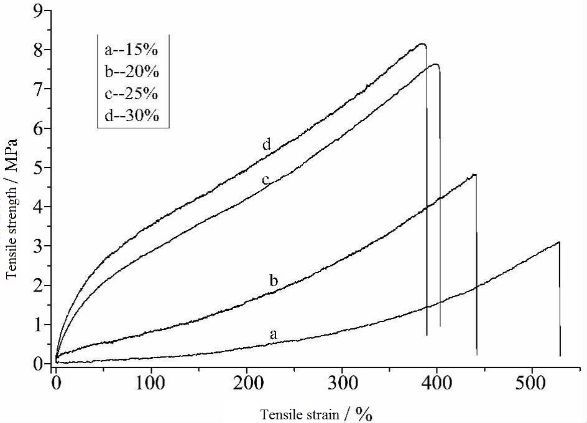

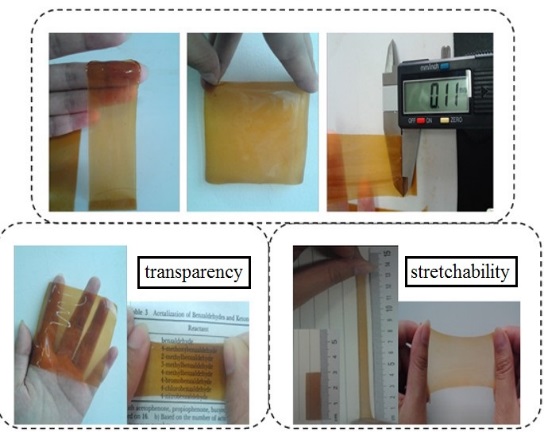

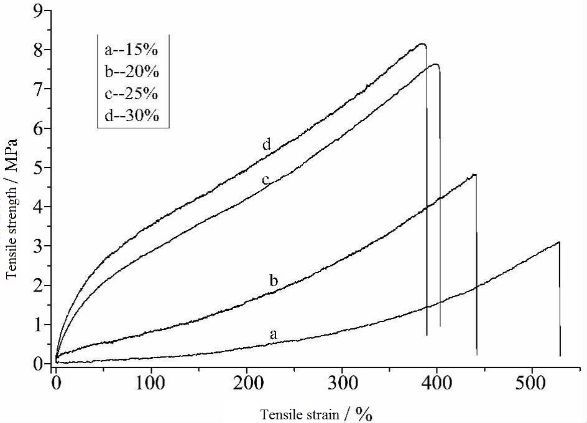

Furthermore, researchers prepared the smooth and compact hemicellulose films by mixing the pre-hydrolysis extracted hemicelluloses and polyvinyl alcohol (PVA) via tape casting method. The tensile strength and breaking length of the prepared films could reach 7.63 MPa and 403% respectively. This kind of hemicellulose films could be used for package so to replace plastic films (Pap. Sci. Technol., 2014, 33: 30).

Fig. 3 The process of combined deacetylation and PFI refining for the improvement of enzymatic hydrolysis and its impact on the final total sugar yields

Fig. 4 Hemicellulose films prepared by pre-hydrolysis extracted hemicelluloses and their strength properties.

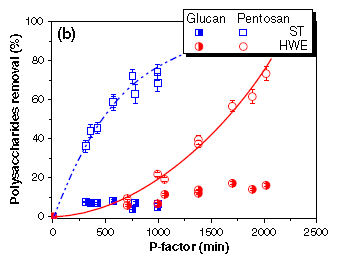

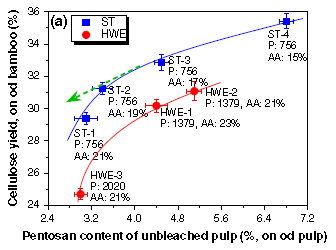

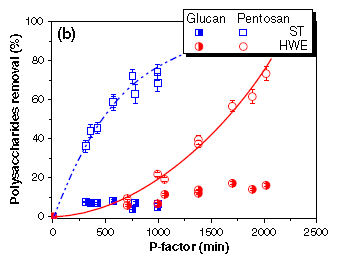

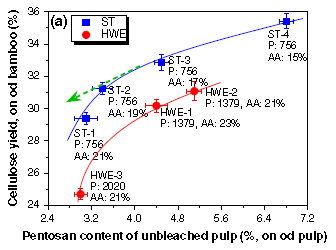

In addition, researchers have compared the purity of dissolving pulp processed using the methods based on two different pretreatment techniques. One was steam pretreatment, and the other was hot-water pretreatment. It was found that with the same removal of pentosan, steam pretreatment could reduce the condensation and re-deposition of lignin. The α-cellulose content of the resulting dissolving pulp could reach 97.6%, and the pulp yield was 3% higher compared to the one with conventional hot water pretreatment (Cellulose, 2014, 3: 1445).

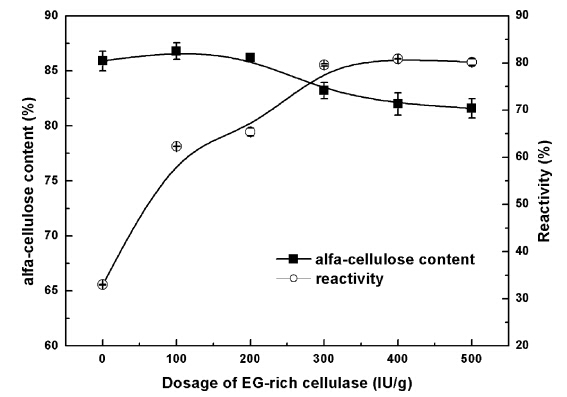

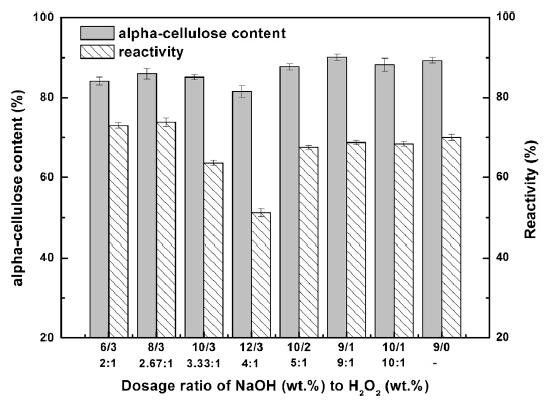

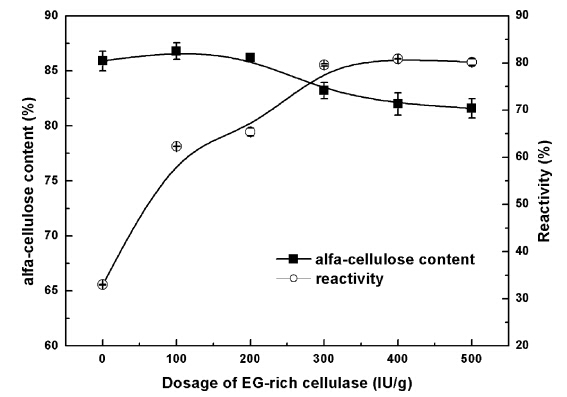

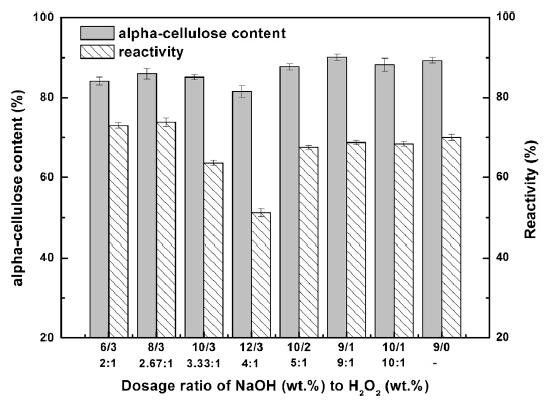

Also, the commercial bleached kraft softwood was treated by a combined enzymatic and chemical method. The α-cellulose content and reactivity of resultant pulp were increased to 90% and 68% respectively. This meets the quality requirements of dissolving pulp for viscos production.

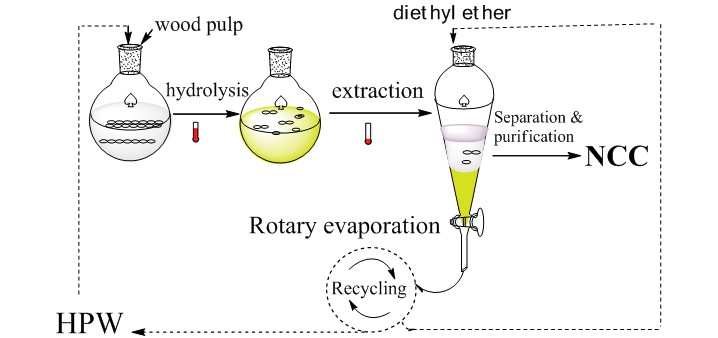

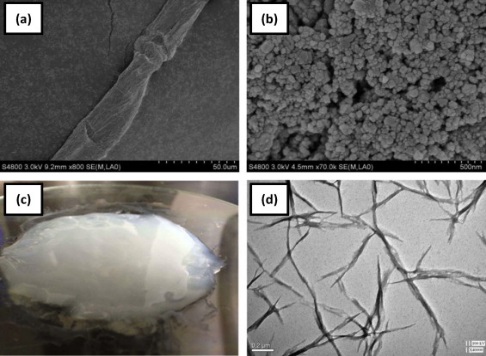

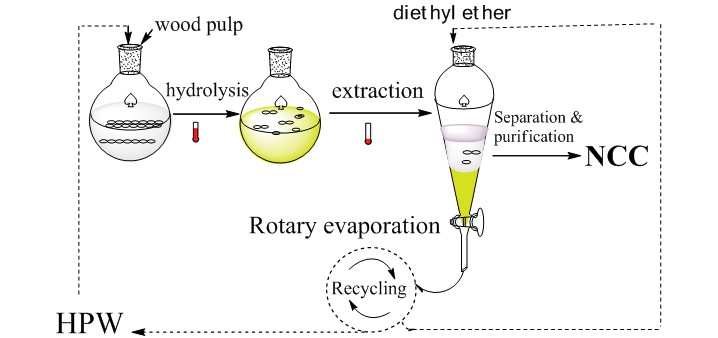

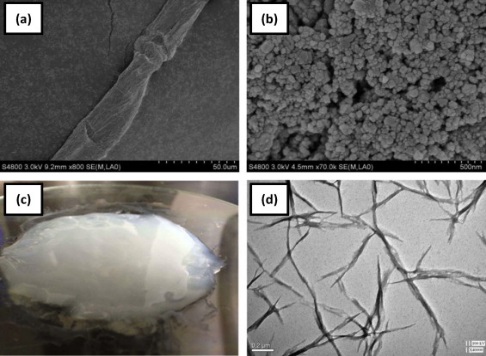

Meanwhile, researchers developed a green and sustainable approach for the preparation of thermal-stable nanocrystalline cellulose (NCC, 15-40 nm in width and 600-800 nm in length). The NCC was treated by solid acid, which could be easily recovered and reused. This lays a basis for the commercial production of NCC (Carbohyd. Polym., 2014, 110: 415).

The above research works were supported by 863 Program of the Ministry of Science and Technology, National Natural Science Foundation of China, and international collaboration projects. These studies were of significant importance for the high value utilization of lignocelluloses and reducing the dependency of fossil resources for the industry of chemical fibers.

Fig. 5 Impact of steam pretreatment and hot water pretreatment on the dissolution of hemicelluloses and cellulose yield

Fig. 6 Effect of combined enzymatic and chemical treatment on α-cellulose content and reactivity of resulting pulp

Fig. 7 The overall process for the preparation of NCC using phosphotungstic acid and the morphology of prepared NCC

(All Images by Green Chemical Engineering Center, QIBEBT)

Reference:

Contact:

Prof. MU Xindong

E-mail: muxd (AT) qibebt.ac.cn

Web: http://english.qibebt.cas.cn

Lignocelluloses are abundant resources on earth. They can be converted to energy, materials, or chemicals to replace the depleting fossil sources. However, it is difficult to achieve efficient conversion due to their natural recalcitrance. The Green Chemical Engineering Center of Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) carried out a series of researches on pretreatment and efficient utilization of inexpensive and renewable lignocelluloses (e.g. corn stover, corn cob, pulp, etc.). The related research progress was published on Bioresour. Technol., J. Agric. Food Chem., Bioproc. Biosyst. Eng., and Carbohyd. Polym., etc.

On the basis of previous researches on the alkaline pretreatment of lignocelluloses (Bioresour. Technol., 2012, 125: 193; Biotechnol. Biofuels, 2013, 6:97), the Pretreatment Group led by professor WANG Haisong has further evaluated the Acetone-Butanol-Ethanol (ABE) fermentability of the resulting fermentable sugars after alkali twin-screw extrusion pretreatment and enzymatic hydrolysis. It was found that the ABE fermentability was comparable to the simulated hydrolyzate medium (the solution containing glucose and xylose with the same ratio and concentration). There were no inhibitors for fermentation and the ABE yield could reach 0.112 g/g raw corn stover (Bioproc. Biosyst. Eng., 2014, 37: 913).

Also, quantitative characterization of the impact of pulp refining on enzymatic saccharification of the alkaline pretreated corn stover was studied. The results showed that the beating degree of PFI refined corn stover was linear with the enzymatic hydrolysis percentage and final total sugar yields. Therefore, the researchers established a simple way to predict enzymatic hydrolysis percentage and final total sugar yields by easily testing the beating degree of refined substrate (Bioresour. Technol., 2014, doi: 10.1016/j.biortech.2014.06.068).

In the meantime, researchers investigated the quantitative analyses of the detailed relationship among the key process parameters in the alkaline pretreatment system. It was found out that the multivariate analysis methods would be a useful tool for optimizing and monitoring the process of biomass conversion in the future commercial production (BioResources, 2014, 9(2): 2757).

Fig. 1 Comparison of the ABE fermentability of the alkali twin-screw extrusion pretreated corn stover and the simulate hydrolyzate Fig. 2 The relationship between beating degree and enzymatic hydrolysis percentage, and the prediction of enzymatic hydrolysis percentage by testing beating degree of the refined corn stover

The researchers also developed a novel approach by combining deacetylation and PFI refining for the improvement of a two-stage enzymatic hydrolysis of corn cob. This approach could efficiently obtain xylo-oligosaccharides (XOS) and glucose separately. In stage one, the resulting enzymatic hydrolyzate contained 56.4% XOS, which was higher than the standard concentration of functional XOS, thus it could be used in the field of medical care, dairy beverage, and food. In stage two, the enzymatic hydrolyzate contained 83.8% of glucose, and the total sugar yields of the two-stage enzymatic hydrolysis were 86.4%. Hence, this approach provided the reference for the pretreatment and full utilization of corn cob (J. Agric. Food Chem., 2014, 62, 4661).

Furthermore, researchers prepared the smooth and compact hemicellulose films by mixing the pre-hydrolysis extracted hemicelluloses and polyvinyl alcohol (PVA) via tape casting method. The tensile strength and breaking length of the prepared films could reach 7.63 MPa and 403% respectively. This kind of hemicellulose films could be used for package so to replace plastic films (Pap. Sci. Technol., 2014, 33: 30).

Fig. 3 The process of combined deacetylation and PFI refining for the improvement of enzymatic hydrolysis and its impact on the final total sugar yields Fig. 4 Hemicellulose films prepared by pre-hydrolysis extracted hemicelluloses and their strength properties.

In addition, researchers have compared the purity of dissolving pulp processed using the methods based on two different pretreatment techniques. One was steam pretreatment, and the other was hot-water pretreatment. It was found that with the same removal of pentosan, steam pretreatment could reduce the condensation and re-deposition of lignin. The α-cellulose content of the resulting dissolving pulp could reach 97.6%, and the pulp yield was 3% higher compared to the one with conventional hot water pretreatment (Cellulose, 2014, 3: 1445).

Also, the commercial bleached kraft softwood was treated by a combined enzymatic and chemical method. The α-cellulose content and reactivity of resultant pulp were increased to 90% and 68% respectively. This meets the quality requirements of dissolving pulp for viscos production.

Meanwhile, researchers developed a green and sustainable approach for the preparation of thermal-stable nanocrystalline cellulose (NCC, 15-40 nm in width and 600-800 nm in length). The NCC was treated by solid acid, which could be easily recovered and reused. This lays a basis for the commercial production of NCC (Carbohyd. Polym., 2014, 110: 415).

The above research works were supported by 863 Program of the Ministry of Science and Technology, National Natural Science Foundation of China, and international collaboration projects. These studies were of significant importance for the high value utilization of lignocelluloses and reducing the dependency of fossil resources for the industry of chemical fibers.

Fig. 5 Impact of steam pretreatment and hot water pretreatment on the dissolution of hemicelluloses and cellulose yield Fig. 6 Effect of combined enzymatic and chemical treatment on α-cellulose content and reactivity of resulting pulp Fig. 7 The overall process for the preparation of NCC using phosphotungstic acid and the morphology of prepared NCC

Reference:

(All Images by Green Chemical Engineering Center, QIBEBT)

Contact:

Prof. MU Xindong

E-mail: muxd (AT) qibebt.ac.cn

Web: http://english.qibebt.cas.cn

CAS Institutes

There are 124 Institutions directly under the CAS by the end of 2012, with 104 research institutes, five universities & supporting organizations, 12 management organizations that consist of the headquarters and branches, and three other units. Moreover, there are 25 legal entities affiliated and 22 CAS invested holding enterprisesThere are 124 I...>> more

Contact Us

Chinese Academy of Sciences

Add: 52 Sanlihe Rd., Xicheng District, Beijing, China

Postcode: 100864

Tel: 86-10-68597592 (day) 86-10-68597289 (night)

Fax: 86-10-68511095 (day) 86-10-68512458 (night)

E-mail: cas_en@cas.cn