Twin Boundary: Stronger or Weaker Interface to Resist Fatigue Cracking?

Apr 10, 2014 Email"> PrintText Size

It is well-known that grain boundaries (GBs) play a crucial role in mechanical properties of materials, especially the twin boundary (TB) which could improve the strength and ductility of materials synchronously has attracted much research attention. Prof. ZHANG Zhefeng’s group in Materials Fatigue and Fracture division of Shenyang National Laboratory for Materials Science (SYNL) has done a series of low-cycle fatigue experiments on bicrystals with high- or low- angle GBs and polycrystals with TBs. It was demonstrated that low-angle GBs are the strongest in resisting fatigue cracking, high-angle GBs are the weakest, and TBs are in between which is associated with the stacking fault energy and grain orientation.

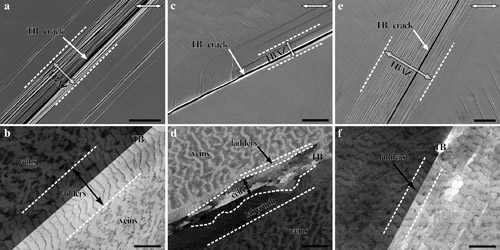

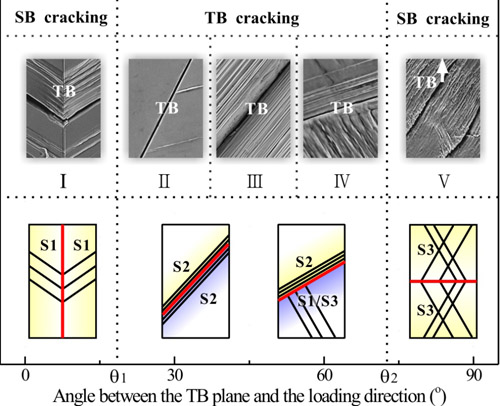

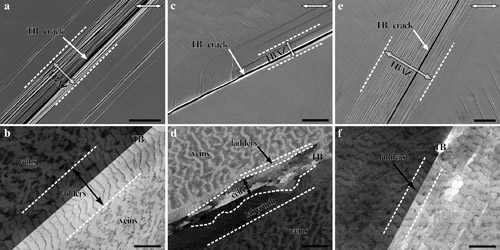

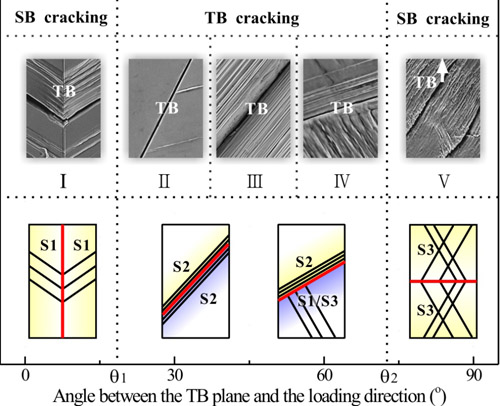

To further reveal the origins of TBs during cyclic deformation, Drs. LI Linlin and ZHANG Zhenjun prepared Cu bicrystals with a sole coherent or incoherent TB and designed a series of fatigue experiments. It was found that different from high- or low- angle GBs, the fatigue cracking mechanisms of the coherent TBs are concerned with the TB inclination angle with respect to the loading direction. As shown in Figure 1, when the angle between the TB and the loading direction is between about 20~70°, the slip bands parallel to the TB tend to concentrate at the TB with shear damage which leads to the preferential TB fatigue cracking. When the TB is parallel or perpendicular to the loading direction, the slip bands in the grain interior sustain the main plastic deformation and there is good strain compatibility near the TB. Hence the fatigue cracking nucleates along the slip bands preferentially. As summarized in Figure 2, the connection between the inclination angles and the fatigue cracking mechanisms are figured out for the first time, which provides possibility for controlling the fatigue cracking resistance of materials.

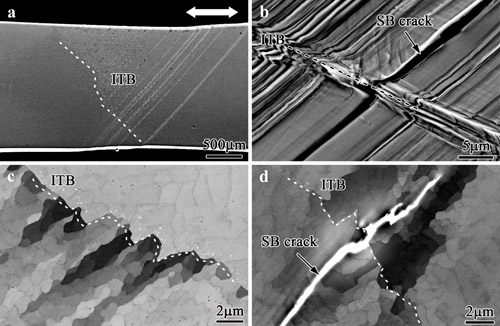

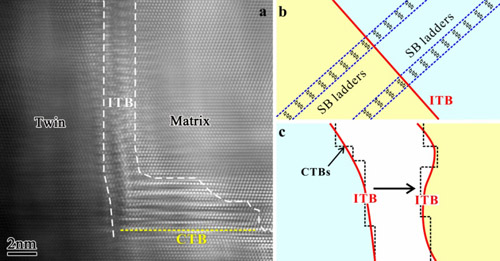

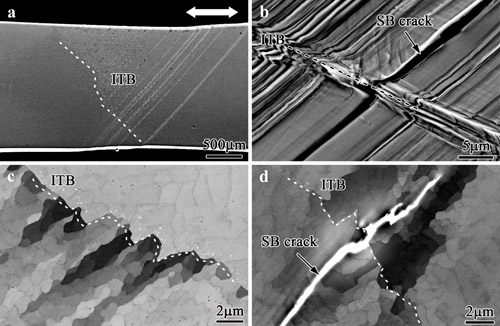

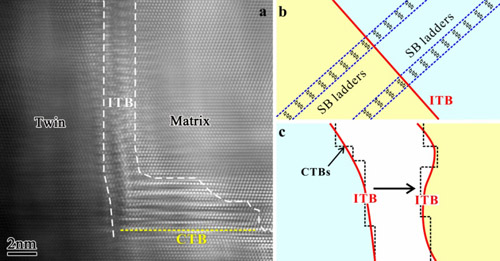

Generally, there are also abundant incoherent TBs coexisting with coherent TB in materials with deformation, annealing or growth twins. It is desirable to investigate the fatigue cracking mechanisms of incoherent TBs which lacks clarification so far. It is found that under certain circumstance, the slip bands (SBs) are continuous across the incoherent TB and the fatigue crack nucleates along the SBs preferentially as shown in Figures 3a and 3b. The dislocation arrangements are shown in Figure 3c and 3d which demonstrate that the fatigued incoherent TB has evolved into parts of dislocation cells. Due to the special crystallographic orientation, the SBs could transfer through the ITB; meanwhile, the ITB could migrate with the motion of partial dislocations as illustrated in Figure 4a. Both the penetrability and mobility relieve the stress of dislocation pileups at the inteface and contribute to the high fatigue cracking resistance of the incoherent TB. The mechanisms are sketched in Figures 4b and 4c. These results could provide new and important implications for the optimized interfacial design of the high-performance materials. The relevant works about the coherent and incoherent TBs have been published in Acta Materialia, 61 (2013) 425, Scientific Reports, 4 (2014) 3744, Nature Communications, 5 (2014) 3536 & Acta Materialia, 2014.

Figure 1: Surface morphologies and dislocation arrangements of the bicrystals with an inclined TB. (Image by IMR)

Figure 2: General fatigue cracking mechanisms of the twinned bicrystals with all possible TB inclinations. (Image by IMR)

Figure 3: The surface deformation morphology and subsurface dislocation arrangement of the fatigued bicrystal. (Image by IMR)

Figure 4: The high-resolution TEM observation of the fatigued ITB and the sketch for the dislocation penetration and ITB migration. (Image by IMR)

Contact:

ZHANG Zhefeng

Materials Fatigue and Fracture Division, Shenyang National Laboratory for Materials Sciences, Institute of Metal Research, Chinese Academy of Sciences

72 Wenhua Road, Shenyang, 110016, P. R. China

E-mail: zhfzhang@imr.ac.cn

It is well-known that grain boundaries (GBs) play a crucial role in mechanical properties of materials, especially the twin boundary (TB) which could improve the strength and ductility of materials synchronously has attracted much research attention. Prof. ZHANG Zhefeng’s group in Materials Fatigue and Fracture division of Shenyang National Laboratory for Materials Science (SYNL) has done a series of low-cycle fatigue experiments on bicrystals with high- or low- angle GBs and polycrystals with TBs. It was demonstrated that low-angle GBs are the strongest in resisting fatigue cracking, high-angle GBs are the weakest, and TBs are in between which is associated with the stacking fault energy and grain orientation.

To further reveal the origins of TBs during cyclic deformation, Drs. LI Linlin and ZHANG Zhenjun prepared Cu bicrystals with a sole coherent or incoherent TB and designed a series of fatigue experiments. It was found that different from high- or low- angle GBs, the fatigue cracking mechanisms of the coherent TBs are concerned with the TB inclination angle with respect to the loading direction. As shown in Figure 1, when the angle between the TB and the loading direction is between about 20~70°, the slip bands parallel to the TB tend to concentrate at the TB with shear damage which leads to the preferential TB fatigue cracking. When the TB is parallel or perpendicular to the loading direction, the slip bands in the grain interior sustain the main plastic deformation and there is good strain compatibility near the TB. Hence the fatigue cracking nucleates along the slip bands preferentially. As summarized in Figure 2, the connection between the inclination angles and the fatigue cracking mechanisms are figured out for the first time, which provides possibility for controlling the fatigue cracking resistance of materials.

Generally, there are also abundant incoherent TBs coexisting with coherent TB in materials with deformation, annealing or growth twins. It is desirable to investigate the fatigue cracking mechanisms of incoherent TBs which lacks clarification so far. It is found that under certain circumstance, the slip bands (SBs) are continuous across the incoherent TB and the fatigue crack nucleates along the SBs preferentially as shown in Figures 3a and 3b. The dislocation arrangements are shown in Figure 3c and 3d which demonstrate that the fatigued incoherent TB has evolved into parts of dislocation cells. Due to the special crystallographic orientation, the SBs could transfer through the ITB; meanwhile, the ITB could migrate with the motion of partial dislocations as illustrated in Figure 4a. Both the penetrability and mobility relieve the stress of dislocation pileups at the inteface and contribute to the high fatigue cracking resistance of the incoherent TB. The mechanisms are sketched in Figures 4b and 4c. These results could provide new and important implications for the optimized interfacial design of the high-performance materials. The relevant works about the coherent and incoherent TBs have been published in Acta Materialia, 61 (2013) 425, Scientific Reports, 4 (2014) 3744, Nature Communications, 5 (2014) 3536 & Acta Materialia, 2014.

Figure 1: Surface morphologies and dislocation arrangements of the bicrystals with an inclined TB. (Image by IMR)

Figure 2: General fatigue cracking mechanisms of the twinned bicrystals with all possible TB inclinations. (Image by IMR)

Figure 3: The surface deformation morphology and subsurface dislocation arrangement of the fatigued bicrystal. (Image by IMR)

Figure 4: The high-resolution TEM observation of the fatigued ITB and the sketch for the dislocation penetration and ITB migration. (Image by IMR)

Contact:

ZHANG Zhefeng

Materials Fatigue and Fracture Division, Shenyang National Laboratory for Materials Sciences, Institute of Metal Research, Chinese Academy of Sciences

72 Wenhua Road, Shenyang, 110016, P. R. China

E-mail: zhfzhang@imr.ac.cn

CAS Institutes

There are 124 Institutions directly under the CAS by the end of 2012, with 104 research institutes, five universities & supporting organizations, 12 management organizations that consist of the headquarters and branches, and three other units. Moreover, there are 25 legal entities affiliated and 22 CAS invested holding enterprisesThere are 124 I...>> more

Contact Us

Chinese Academy of Sciences

Add: 52 Sanlihe Rd., Xicheng District, Beijing, China

Postcode: 100864

Tel: 86-10-68597592 (day) 86-10-68597289 (night)

Fax: 86-10-68511095 (day) 86-10-68512458 (night)

E-mail: cas_en@cas.cn